9

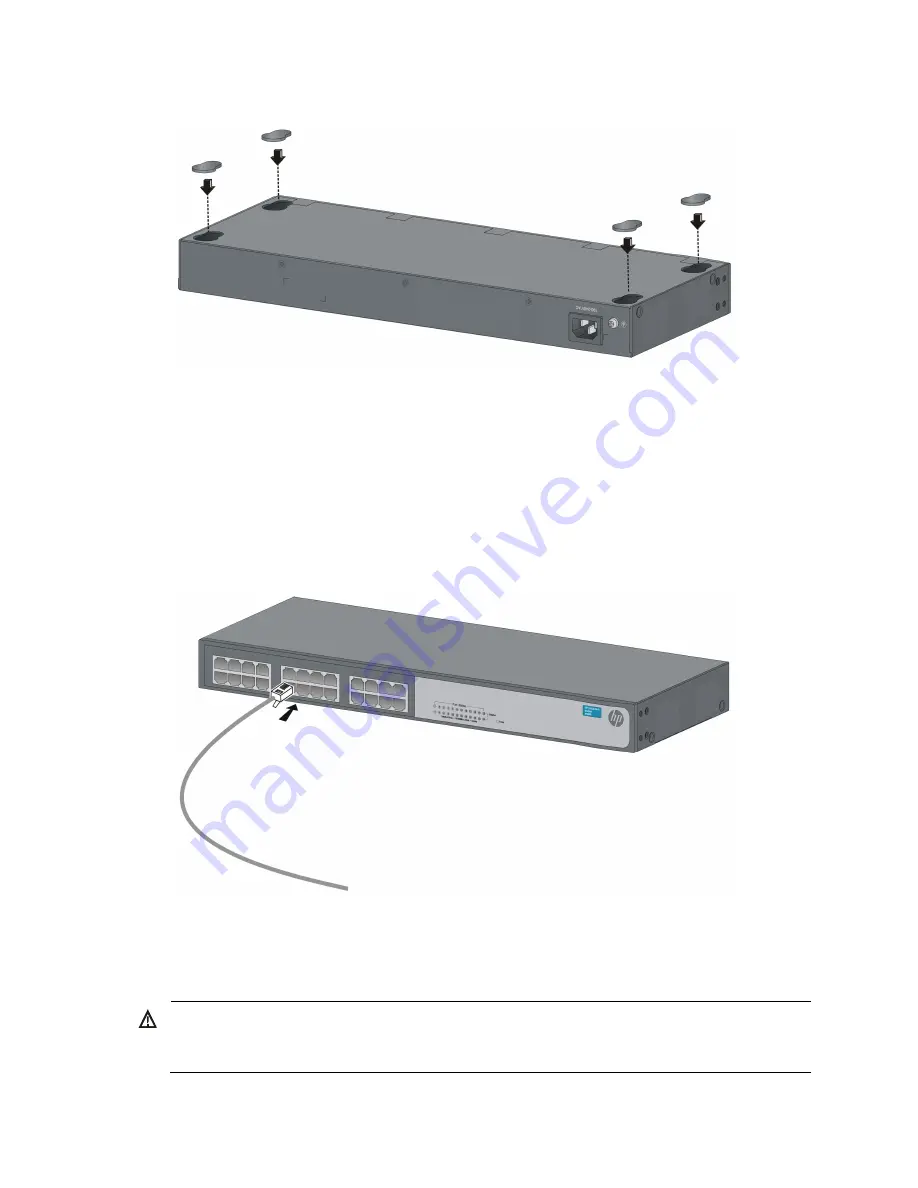

Figure 3

Attaching rubber feet

Connecting cables

Connecting network cable

Use crossover cables or straight-through cables to connect a PC or other network devices to the Ethernet

port of the switch.

Figure 4

Connecting network cable

Connecting the AC power cord

WARNING!

Make sure the grounding cable is securely connected and the switch is well grounded before connecting

the AC power cord.