ISRB-2009, Rev. 02_17.

8

Troubleshooting Checklist

Trouble

Item

Possible Cause

Remedy

No flow

1

2

3

Speed too low

Wrong rotation

Obstruction in piping

Check by tachometer and compare with published

performance.

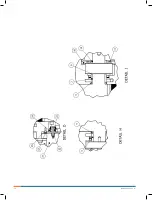

Compare actual rotation with Figure 1, change driver if wrong.

Check piping, valves, silencer to assure open flow path.

Low capacity

4

5

6

7

Speed too low

Excessive pressure

rise

Obstruction in piping

Excessive slip

See item 1, if belt drive, check for slippage and re-adjust

tension.

Check inlet vacuum and discharge pressure and compare with

published performance.

See item 3.

Check inside of casing for worn or eroded surfaces causing

excessive clearances

Excessive power

8

9

10

11

Speed too high

Excessive pressure

rise

Impeller rubbing

Scale, sludge, rust or

product build up

Check speed and compare with published performance.

See item 5

Inspect outside of cylinder for high temperature areas, then check

for impeller contact at these points. Correct blower mounting, drive

alignment.

Clean blower appropriately

Damage to bearings

or gears

12

13

14

15

16

Inadequate

lubrication

Excessive

lubrication

Excessive

pressure rise

Coupling

misalignment

Excessive belt

tension

Check oil sump levels in gear and drive end headplates

Check oil levels. If correct, drain and refill with clean oil of

recommended grade.

See item 5.

Check carefully. Re-align if questionable.

Re-adjust for correct tension.

Vibration

17

18

19

20

21

22

23

24

Misalignment

Impellers rubbing

Worn bearings/gears

Unbalanced or

rubbing impeller

Driver or blower

loose

Piping resonances

Scale/sludge

build-ups

Casing strain

See item 15

See item 10

Check gear backlash and conditions of bearings and replace as

indicated.

Scale or process material may build up on casing and impellers, or

inside impellers. Remove build-up to restore original clearances and

impeller balance.

Tighten mounting bolts securely.

Determine whether standing wave pressure pulsations are present

in the piping.

Clean out interior of impeller lobes to restore dynamic balance.

Re-work piping alignment to remove excess strain.

Driver stops, or will

not start

25

26

Impeller stuck

Scale, sludge, rust or

product build-up

Check for excessive hot spot on headplate or cylinder.

See item 10. Look for defective shaft bearing and/or gear

teeth.

Clean blower appropriately

Summary of Contents for Roots 412 HPT

Page 1: ...www howden com Roots 412 HPT Blower Installation Operation Maintenance Manual...

Page 11: ...11 ISRB 2009 Rev 02_17...

Page 12: ...ISRB 2009 Rev 02_17 12...

Page 13: ...13 ISRB 2009 Rev 02_17...

Page 14: ...ISRB 2009 Rev 02_17 14...

Page 15: ...15 ISRB 2009 Rev 02_17...