12

13

Assembly and operating manual aquagen

7149029926 V1.3 (09.2018)

Assembly and operating manual aquagen

7149029926 V1.3 (09.2018)

2 Functional Principle of the aquagen

When using the aquagen recombination system, the oxyhydrogen mixture which develops during the water

decomposition in the battery is led to the aquagen recombinator. This gas is recombined by means of an inte-

grated catalyst with water vapour developing during the process. The water vapour condenses at the walls of

the aquagen recombinator. The developing water drops flow down and are returned to the battery. Depending

on the conditions, the efficiency of this recombination is up to 99%. This effectively reduces the efforts for the

refilling of water. We recommend a visual inspection of the electrolyte level at least twice per year.

Due to the recombination of the developing gases, the ventilation requirements according to EN 50272-2 can

be reduced significantly.

For battery cells/ blocks with a capacity of max. 500 Ah C10 or when using NiCd-battery cells at

a capacitiy of max. 450 Ah C5, it is possible to use the

grid |

aquagen

pro

. For higher capacities

the

grid |

aquagen

pro max

is the right choise.

Attention!

Aquagen recombinators may only be operated with HOPPECKE batteries (closed construction/

VLA).

3 Assembly of the aquagen

Danger!

Before starting to work in the battery room, you must ensure that the ventilation is operative. In

case of technical ventilation, it must be switched on while working on the batteries.

Danger!

Observe all aforementioned safety instructions and safety precautions, in particular with regards

to the leak resistances of gloves and safety boots (see

chap. 1.3

) as well as the floor area in the

battery room (see

chap. 1.4.3

).

Danger!

Before attaching the aquagen recombinator, and if the electrolyte level has fallen to the “min.”

mark during the operation of the battery system, the electrolyte level has to be restored by refilling

cleaned/desalinated water (DIN 43530 part 4/IEC 60993-1). Overfilling beyond the “max.” mark

must be avoided.

3.1 Removing the labyrinth insert using screwdriver

In order to loosen the labyrinth insert from the bayonet plug, a screwdriver gets inserted between the labyrinth

insert and the bayonet plug and pulled off towards the top while pressing on the bottom edge. After the labyrinth

insert is loosen from the bayonet plug, it can be picked up with the hand.

Attention!

Attention, there might be electrolyte residues on the labyrinth insert. The labyrinth inserts should

be placed and later stored in a suitable container.

3.2 Inserting the aquagen

If the aquagen is mounted on older batteries, it is necessary to replace the old battery plugs with

a bayonet plug.

Attention!

Aquagen products with visible damages caused by falling, collisions or similar must not be used.

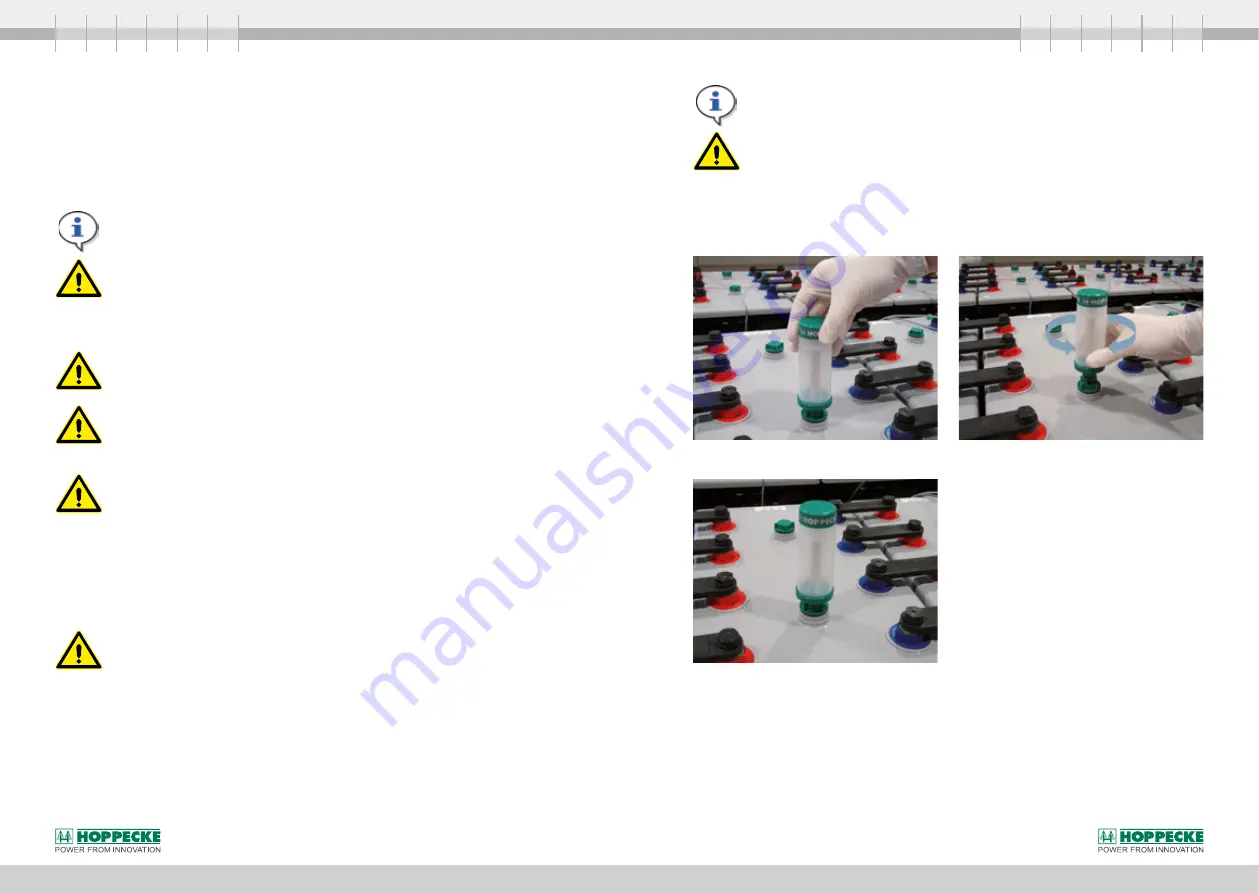

The aquagen is vertically inserted into the correspondingly prepared bayonet plug (

Figure 1

), and is pressed into

the bayonet plug until reaching the stop by means of slight rotary movements (

Figure 2

).

Now, the aquagen is fully mounted (

Figure 3

).

Figure 1: Inserting the aquagen I

Figure 3: Assembly of aquagen

Figure 2: Inserting the aquagen II