VRW2 DYNAMIC PRESSURE- REGULATING FLANGED CONTROL VALVES

9

62-3116—01

OPERATION AND CHECKOUT

Once both the mechanical and electrical installations are

complete:

1.

Cycle the actuator to verify that the direction of rotation

suits the control sequence.

2.

If the rotation direction is incorrect:

a. For floating control actuators: Reverse two control

signal wires (CW/CCW), or change position of selec-

tor switches.

b. For analog control actuators, change position of

selector switches.

3.

If the control scheme requires fail-safe operation, ensure

that, upon removal of power, the fail position coincides

with the control sequence.

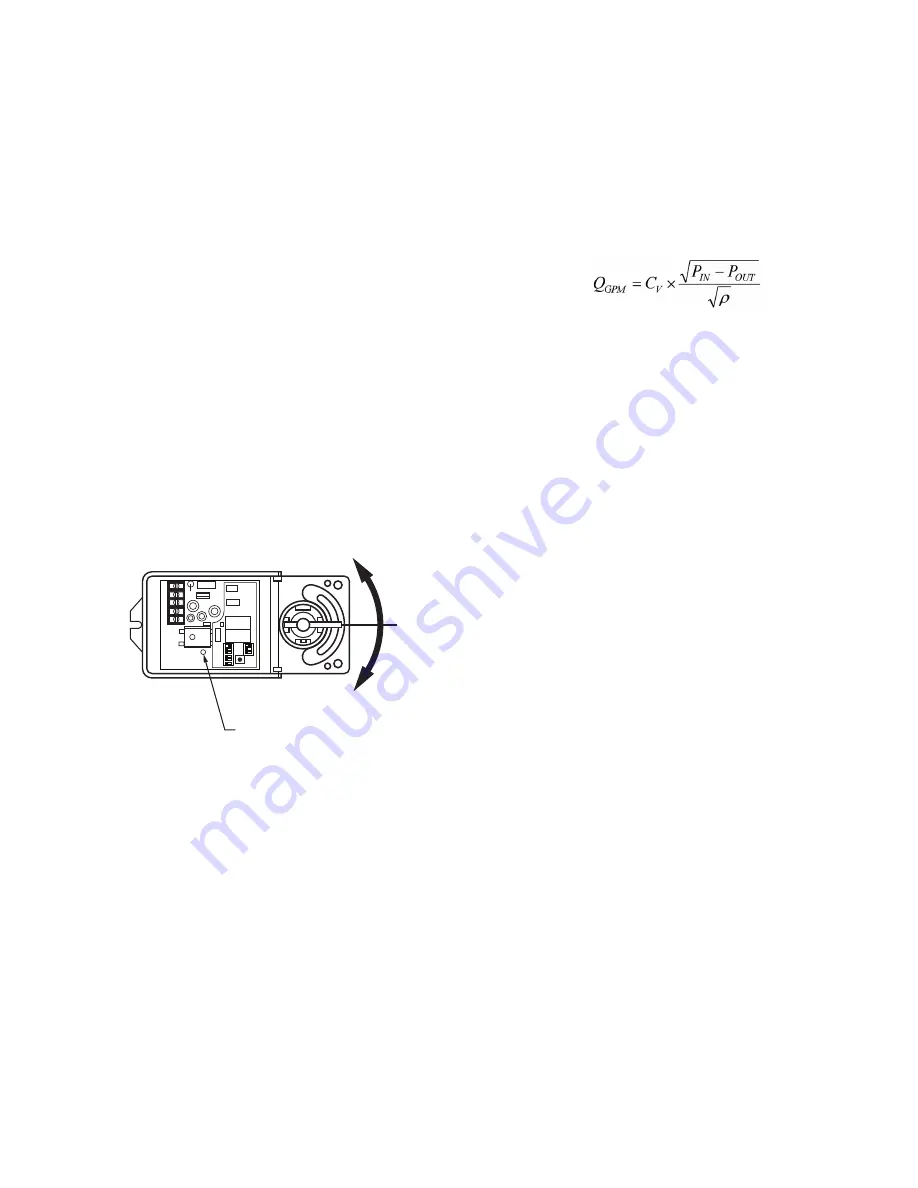

Manual Override

1.

Remove Actuator cover and DISCONNECT POWER

before operating actuator manually.

NOTE: Failure to disconnect power may cause dam-

age to the actuator gears.

2.

Press the clutch.

3.

Rotate valve stem to manually operate valve. Clockwise

to close, Counter-Clockwise to open. See Fig. 11.

Fig. 11. Manual Operation.

MAINTENANCE

1.

Continual blinking indicates that the Actuator torque out-

put limit has been exceeded. This may have been

caused by debris in the valve internals. Disconnect

power and manually operate the valve to clear the

debris. Reconnect power. The Actuator will automatically

recalibrate and reset. If the problem reoccurs, inspect

the valve body internally for debris.

2.

If the system experiences large amounts of pipe scale

due to poor water conditions, as sometimes found in

older or retrofit pipe systems, provisions should be made

to keep the system clean. Proper water treatment is also

recommended by the use of a Separator.

3.

If a separator is not used for system cleaning and filtra-

tion, the valves should be checked annually.

Operation

The differential pressure regulator maintains constant pressure

drop (P

IN

- P

OUT

) across the valve seat through a wide range

of head pressures. At a given shaft position, flow through the

valve will constant as defined by the formula:

where

ρ

is the density of the glycol mix.

P

IN

changes constantly in a multi-zone system as other valves

open and close, changing system flow and head pressure

according to the characteristics of the supply pump curve.

Reaction of the mechanical pressure regulator is

instantaneous, eliminating changes in room temperature due

to changes in fluid flow, and reducing the need for the control

system to constantly operate the control portion of the valve to

correct for the non-load related temperature changes that

occur in a system with standard control valves.

At full flow in a 2-position control application, a VRW2 behaves

as a flow limiter.

The pressure regulator takes a minimum pressure to operate,

and has a maximum differential regulation capability. The

pressure drop across a VRW Valve is comparable to the

pressure drop across a control valve plus a balancing valve in

a conventional system design.

SETTINGS AND ADJUSTMENTS

At the full open position, VRW valves will maintain flow at the

gallons per minute rate determined by the DIP Switch settings

shown in Table 4. Under steady state operation, the control

system will only require the valve to open enough to satisfy

load conditions. During morning recovery from night setback,

the controller will usually command the valve to 100%.

Coil flow can be confirmed by reading pressures at the supply

inlet and return outlet, and using the system design data to

calculate flow.

Note that the pressure regulator in this valve guarantees that

the flow through the valve will not be affected by upstream

changes in pressure. Unlike conventional balancing valves, it

is not necessary to reconfirm flow after adjusting other valves.

Any overflow during morning recovery due to oversized

pressure regulated valves will not affect other valves in the

system, provided pumps are capable of required flow.

M31293

CLOSE

OPEN

CLUTCH PUSH BUTTON

1

ON

23

4

5

6

1

ON

23

1 2 3 4 5

88