7

68-0049—2

VR8205; VR4205

␣ ␣ ␣ INSTALLATION

WIRING

Follow the wiring instructions furnished by the appli-

ance manufacturer, if available, or use the general instruc-

tions provided below. Where these instructions differ from

the appliance manufacturer, follow the appliance manufac-

turer instructions.

All wiring, including insulated quick connect terminals,

must comply with applicable electrical codes and ordi-

nances.

Disconnect power supply before making wiring connec-

tions to prevent electrical shock or equipment damage.

1. Check the power supply rating on the valve and make

sure it matches the available supply. Install transformer,

thermostat, and other controls as required.

2. For VR4205, when the gas control is installed exter-

nal to the appliance, install the conduit cover on the conduit

fitting. Do not secure conduit cover at this time.

3. Connect control circuit to gas control terminals. See

Figs. 5 and 7-9.

NOTE: Use leadwires with insulated terminals.

4. For VR4205, make sure conduit cover is in position

and secured to the gas valve with the screw provided. See

Fig. 2.

5. Adjust thermostat heat anticipator as instructed in

appliance manual (i.e., usually 0.1A for VR4205 and 0.5A

for VR8205).

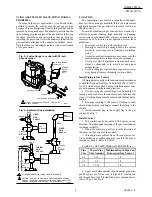

Fig. 7—Wiring connections for 120 volt control

in direct ignition system.

Fig. 8—Wiring connections for 24 volt control

in S87 Direct Ignition System.

IGNITION MODULE

L1

(HOT)

L2

LIMIT CONTROLLER

Q347 IGNITER-SENSOR

120V (GND)

VALVE

VALVE

GND

POWER SUPPLY. PROVIDE DISCONNECT MEANS

AND OVERLOAD PROTECTION AS REQUIRED.

ALTERNATE LIMIT CONTROLLER LOCATION.

M3090A

BURNER

120V

VR4205

DUAL VALVE

COMBINATION

GAS CONTROL

L2

L1

2

1

1

2

WHITE

BLUE

BLACK

BLUE

HOT

SURFACE

IGNITER-

SENSOR

VALVE

VALVE (GND)

24V

TH-W

24V (GND)

GND (BURNER)

S89C,G,J/S890C,G,J

HOT SURFACE

IGNITION CONTROL

L2

HSI

L1

HSI

LIMIT

CONTROLLER

BURNER

GROUND

THERMOSTAT

OR CONTROLLER

DUAL VALVE

COMBINATION

GAS CONTROL

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

PROTECTION AS REQUIRED. MAKE SURE L1 AND L2 ARE NOT

REVERSED; THIS WOULD PREVENT FLAME DETECTION.

ALTERNATE LIMIT CONTROLLER LOCATION.

SEN TERMINAL AND Q354 FLAME SENSOR ON D MODELS ONLY.

M9047

MV

MV

L1

(HOT)

L2

VENT

DAMPER PLUG

1

2

1

2

3

3

SEN

Q354 FLAME

SENSOR

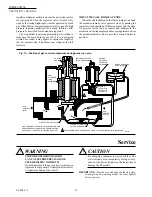

Fig. 9—Wiring connections for 24 volt control

in S89C Direct Ignition System.

24V

24V (GND)

S87 CONTROL MODULE

ALARM

VALVE

VALVE

GND

TEMPERATURE

CONTROLLER

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

PROTECTION AS REQUIRED.

ALTERNATE LIMIT CONTROLLER LOCATION.

MAXIMUM IGNITER-SENSOR CABLE LENGTH: 3 ft. [.9 m] OR LESS.

3 A REPLACEABLE FUSE.

ALARM TERMINAL PROVIDED ON SOME MODELS.

M9043

MV

MV

L1

(HOT)

L2

1

2

1

2

3

DUAL VALVE

COMBINATION

GAS CONTROL

Q347 IGNITER-SENSOR

BURNER

4

4

5

IGNITER-SENSOR AND

BURNER GROUND

3

5

ALARM, IF USED