2

control.

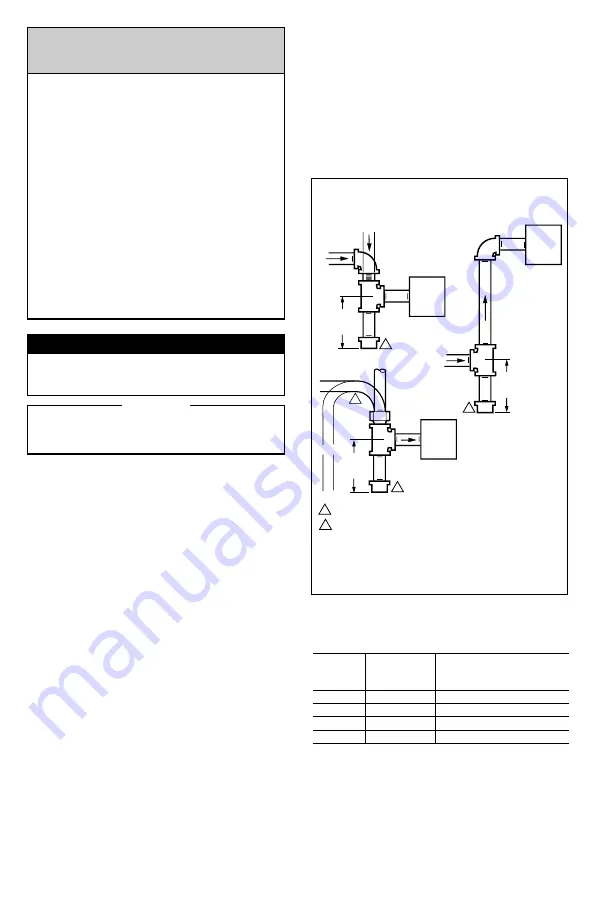

3. Install sediment trap in gas supply line. Refer to Fig. 1.

INSTALL CONTROL

1. This control can be mounted 0-90 degrees, in any

direction, from the upright position of the gas control knob,

including vertically.

2. Mount the control so gas flow is in direction of arrow

on bottom of control.

3. Thread pipe the amount shown in Table 3 for insertion

into control. DO NOT THREAD PIPE TOO FAR. Valve

distortion or malfunction may result if pipe is inserted too

deeply.

WARNING

FIRE OR EXPLOSION HAZARD

CAN CAUSE PROPERTY DAMAGE, SEVERE IN-

JURY, OR DEATH

Follow these warnings exactly:

1. Disconnect power supply before wiring to prevent

electrical shock or equipment damage.

2. To avoid dangerous accumulation of fuel gas, turn

off gas supply at appliance service valve before

starting installation and perform Gas Leak Test

following installation.

3. Do not bend pilot gas tubing at control or at pilot

burner after compression fitting is tightened. Gas

leakage at the connection may result.

4. Always install sediment trap in gas supply line to

prevent contamination of gas control.

5. Do not force gas control knob. Use only your hand

to turn gas control knob. If the knob will not operate

by hand, the control should be replaced by a

qualified service technician. Force or attempted

repair may result in fire or explosion.

CAUTION

Never apply a jumper across (or short) gas control

coil terminals. This may burn out thermostat heat

anticipator.

IMPORTANT

These gas controls are shipped with protective seals

over inlet and outlet tappings. Do not remove seals

until ready to connect piping.

Follow the appliance manufacturer’s instructions if avail-

able; otherwise, use the instructions provided below as a

guide.

CHOOSE LOCATION

Do not locate the combination gas control where it may

be affected by steam cleaning, high humidity, dripping

water, corrosive chemicals, dust or grease accumulation,

or excessive heat. To ensure proper operation, follow these

guidelines.

•

Locate in a well ventilated area.

•

Mount high enough above the cabinet bottom to

avoid exposure to flooding or splashing water.

•

Ensure the ambient temperature does not exceed the

ambient temperature ratings for each component.

•

Cover gas control if appliance is cleaned with water,

steam, or chemicals or to avoid dust and grease

accumulation.

•

Avoid locating where exposure to corrosive chemical

fumes or dripping water are likely.

Mount combination gas control in the appliance vesti-

bule on the gas manifold. In replacement applications,

mount gas control in the same location as the old control.

INSTALL PIPING TO CONTROL

All piping must comply with local codes and ordinances

or with National Fuel Gas Code (ANSI Z223.1 NFPA No.

54), whichever applies. Tubing installation must comply

with approved standards and practices.

1. Use new, properly reamed pipe free from chips. If

tubing is used, make sure ends are square, deburred, and

clean. All tubing bends must be smooth and without defor-

mation.

2. Run pipe or tubing to the control. If tubing is used,

obtain a tube-to-pipe coupling to connect tubing to the

TABLE 3—NPT PIPE THREAD LENGTH (IN.).

OVERALL

MAXIMUM DEPTH PIPE

PIPE

THREAD

CAN BE INSERTED

SIZE

LENGTH

INTO CONTROL

3/8

9/16

3/8

1/2

3/4

1/2

3/4

13/16

3/4

1

9/16

1

4. Apply moderate amount of good quality pipe com-

pound to adapter, leaving two end threads bare. Refer to

Fig. 2. (On LP gas installations, use compound resistant to

LP gas.) Do not use Teflon tape.

5. Remove seals over control inlet and outlet, if neces-

sary.

6. Connect pipe to control inlet and outlet. To tighten inlet

and outlet connections, use wrench on projecting wrench

boss. Refer to Figs. 3 and 4.

Fig. 1—Install sediment trap.

GAS

CONTROL

GAS

CONTROL

HORIZONTAL

DROP

PIPED

GAS

SUPPLY

PIPED

GAS

SUPPLY

3 IN.

(76 MM)

MINIMUM

3 IN.

(76 MM)

MINIMUM

RISER

GAS

CONTROL

TUBING

GAS

SUPPLY

HORIZONTAL

DROP

3 IN.

(76 MM)

MINIMUM

RISER

M3077

2

1

2

2

1

2

ALL BENDS IN METALLIC TUBING SHOULD BE SMOOTH.

CAUTION: SHUT OFF THE MAIN GAS SUPPLY BEFORE REMOVING

END CAP TO PREVENT GAS FROM FILLING THE WORK AREA. TEST

FOR GAS LEAKAGE WHEN INSTALLATION IS COMPLETE.