9

68-0047—2

VR8204; VR4204

STARTUP AND CHECKOUT

CHECK AND ADJUST GAS INPUT AND BURNER

IGNITION

CAUTION

1. Do not exceed input rating stamped on appli-

ance nameplate, or manufacturer recommended

burner orifice pressure for size orifice(s) used.

Make certain primary air supply to main burner

is properly adjusted for complete combustion.

Follow appliance manufacturer instructions.

2. IF CHECKING GAS INPUT BY CLOCK-

ING GAS METER. Make certain there is no

gas flow through the meter other than to the

appliance being checked. Other appliances must

remain off with their pilots extinguished (or

their consumption must be deducted from the

meter reading). Convert flow rate to Btuh as

described in form 70-2602, Gas Controls Hand-

book, and compare to Btuh input rating on

appliance nameplate.

3. IF CHECKING GAS INPUT WITH MANO-

METER: Be sure gas control is in OFF posi-

tion before removing outlet pressure tap plug

to connect manometer (pressure gauge). Also

turn gas control knob back to OFF when re-

moving gauge and replacing plug. Before re-

moving inlet pressure tap plug, shut off gas

supply at the manual valve in the gas piping to

the appliance or, for LP, at the tank. Also shut

off gas supply before disconnecting manom-

eter and replacing plug. Repeat Gas Leak Test

at plug with main burner operating.

Standard Pressure Regulator

1. Check the manifold pressure listed on the appliance

nameplate. Gas control outlet pressure should match the

nameplate.

2. With main burner operating, check gas control flow

rate using the meter clocking method or pressure using a

manometer connected to the outlet pressure tap on the gas

control. See Fig. 5.

3. If necessary, adjust pressure regulator to match ap-

pliance rating. See Table 4A or 4B for factory set nominal

outlet pressure and adjustment range.

a. Remove pressure regulator adjustment cap screw.

b. Using screwdriver, turn inner adjustment screw

clockwise

to increase or counterclock-

wise

to decrease gas pressure to burner.

c. Always replace cap screw and tighten firmly to

prevent gas leakage.

4. If desired outlet pressure or flow rate cannot be

achieved to adjusting the gas control, check gas control

inlet pressure using a manometer at the gas control inlet

pressure tap. If inlet pressure is in the nominal range (see

Table 4A or 4B), replace gas control. Otherwise, take the

necessary steps to provide proper gas pressure on the

control.

Slow-opening and Step-opening Pressure Regulators

1. Check the full rate manifold pressure listed on the

appliance nameplate. Gas control full rate outlet pressure

should match this rating.

2. With main burner operating, check gas control flow

rate using the meter clocking method or pressure using a

manometer connected to the outlet pressure tap on the gas

control. See Fig. 5.

3. If necessary, adjust pressure regulator to match ap-

pliance rating. See Table 4A or 4B for factory set nominal

outlet pressure and adjustment range.

a. Remove pressure regulator adjustment screw.

b. Using screwdriver, turn inner adjustment screw

clockwise

to increase or counterclock-

wise

to decrease gas pressure to burner.

c. Always replace cap screw and tighten firmly to

prevent gas leakage.

4. If desired outlet pressure or flow rate cannot be

achieved by adjusting the gas control, check gas control

inlet pressure using a manometer at the gas control inlet

pressure tap. If inlet pressure is in the nominal range (see

Table 4A or 4B), replace gas control. Otherwise, take the

necessary steps to provide proper gas pressure to the con-

trol.

5. STEP-OPENING PRESSURE REGULATORS

ONLY. Carefully check burner lightoff at step pressure.

Make sure burner lights smoothly and without flashback to

orifice. Make sure all ports remain lit. Cycle burner several

times, allowing at least 30 seconds between cycles for

regulator to resume step function. Repeat after allowing

burner to cool. Readjust full rate outlet pressure, if neces-

sary, to improve lightoff characteristics.

!

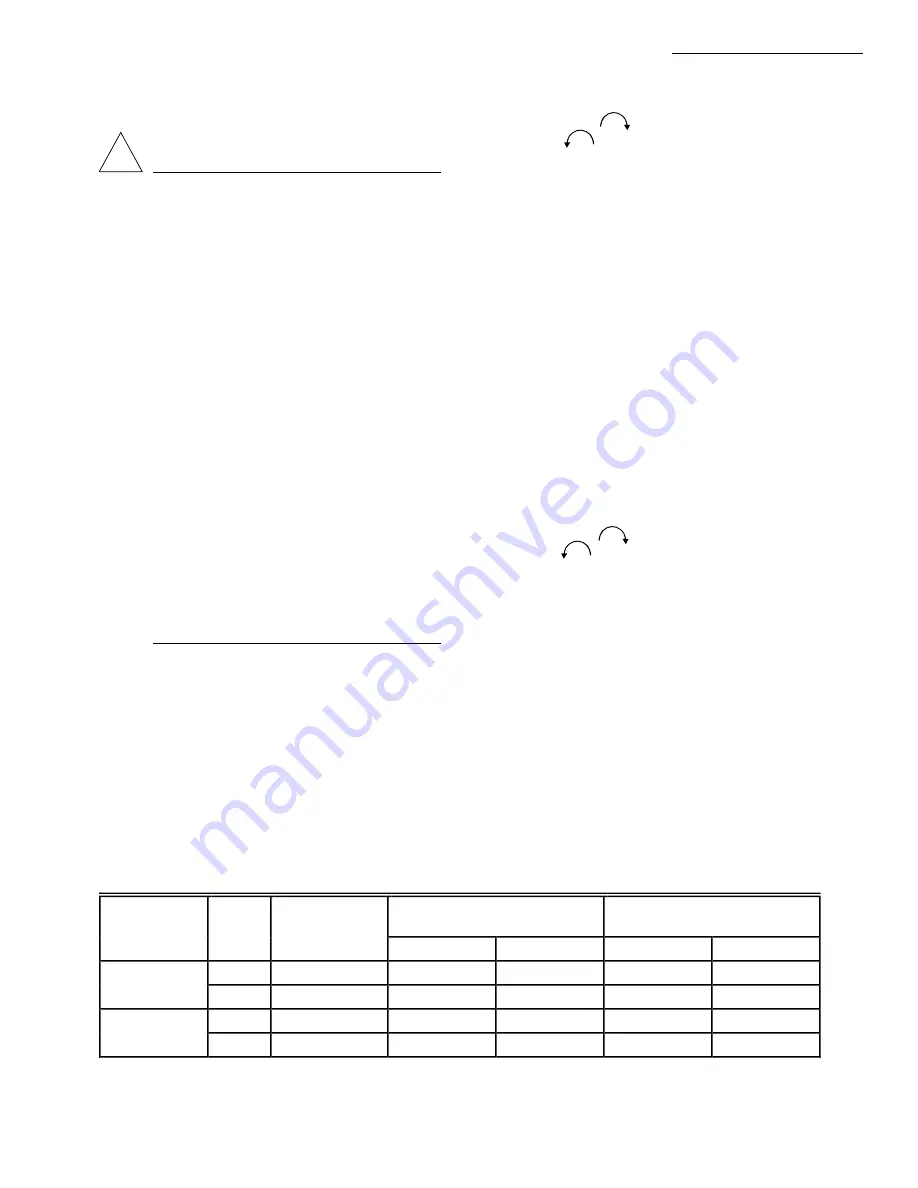

TABLE 4A—PRESSURE REGULATOR SPECIFICATION PRESSURES (in. wc)

Model

Type

Nominal Inlet

Factory Set

Nominal Outlet Pressure

Setting Range

Type

of Gas

Pressure Range

Step

Full Rate

Step

Full Rate

Standard,

Natural

5.0 - 7.0

—

3.5

—

3.0 - 5.0

slow-opening

LP

12.0 - 14.0

—

10.0

—

8.0 - 12.0

Step-opening

Natural

5.0 - 7.0

0.9

3.5

—

3.0 - 12.0

LP

12.0 - 14.0

2.2

10.0

—

8.0 - 12.0

Summary of Contents for TRADELINE VR8204A

Page 15: ...15 68 0047 2 ...