S

CALE

O

PERATION

C

ALIBRATION

Scale Calibration Procedure (lbs. or kg) with Remote Display*

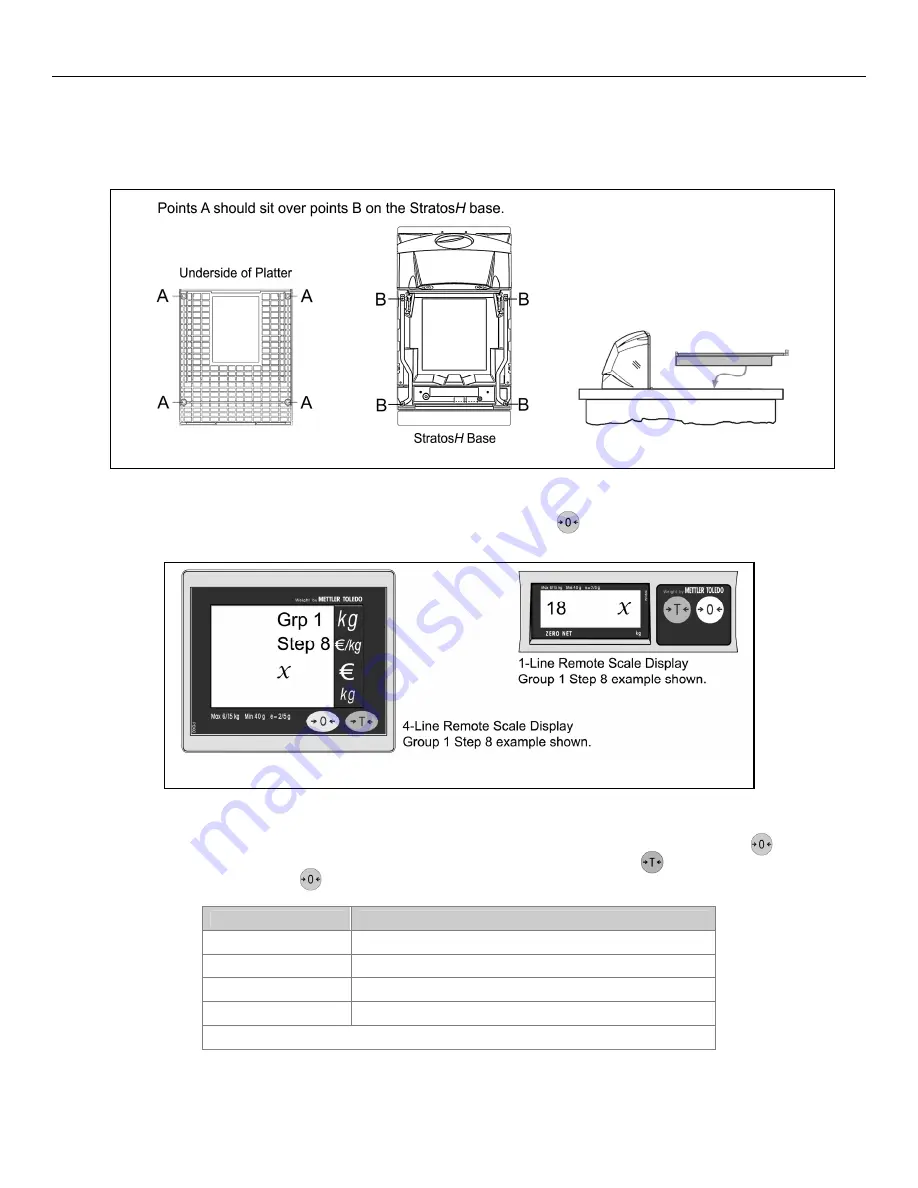

4. Reinstall the platter onto the scanner/scale.

Figure 45. Install Platter

5. Go

to

Group 1 Step 8

(Weight Unit) of the Service Mode by pressing the Zero ( ) key several times until

‘Group 1 Step 8’ is displayed on the Remote Scale Display screen (see

below).

X

Depending on the current Weight Unit setting, this value will either be

1

,

2

,

3

, or

4

.

Figure 46. Remote Scale Display Group 1 Step 8 example shown

6.

Verify the weight unit setting

. Verify the Group 1 Step 8 setting using the table shown below. Press the Zero ( ) key if correct.

If the lb (Pounds) or kg (Kilograms) basic range setting needs to be changed, press the Tare ( ) key to scroll through the

selectable options. Press the Zero ( ) key to accept the selected weight unit range.

Group 1.Step 8 (1.8)

Selectable Weight Unit Ranges

1

lbs range (0 to 30 lbs)

**

2

kg range (0 to 15kg)

3

kg multi-interval (0 to 6kg, 6 to 15kg)

**

4

lbs multi-interval (0 to 15 lbs, 15 to 30 lbs)

**

Common ranges used as default setting.

*

These procedures are for MS2320 StratosH Scanner/

Diva

Scale models only

.

42

Summary of Contents for StratosH MS2320

Page 1: ...MS2320 StratosH Scanner Diva Scale Installation and User s Guide ...

Page 6: ......

Page 75: ......