S

AFETY

Honeywell

• 4

1

a) the

protective earthing conductor

shall have a cross-sectional area of at least 10

mm

2

Cu or 16 mm

2

Al.

or

b) an automatic disconnection of the supply in case of discontinuity of the protective

earthing conductor. See chapter 4.

or

c)

provision of an additional terminal for a second

protective earthing conductor

of the

same cross-sectional area as the original

protective earthing conductor

.

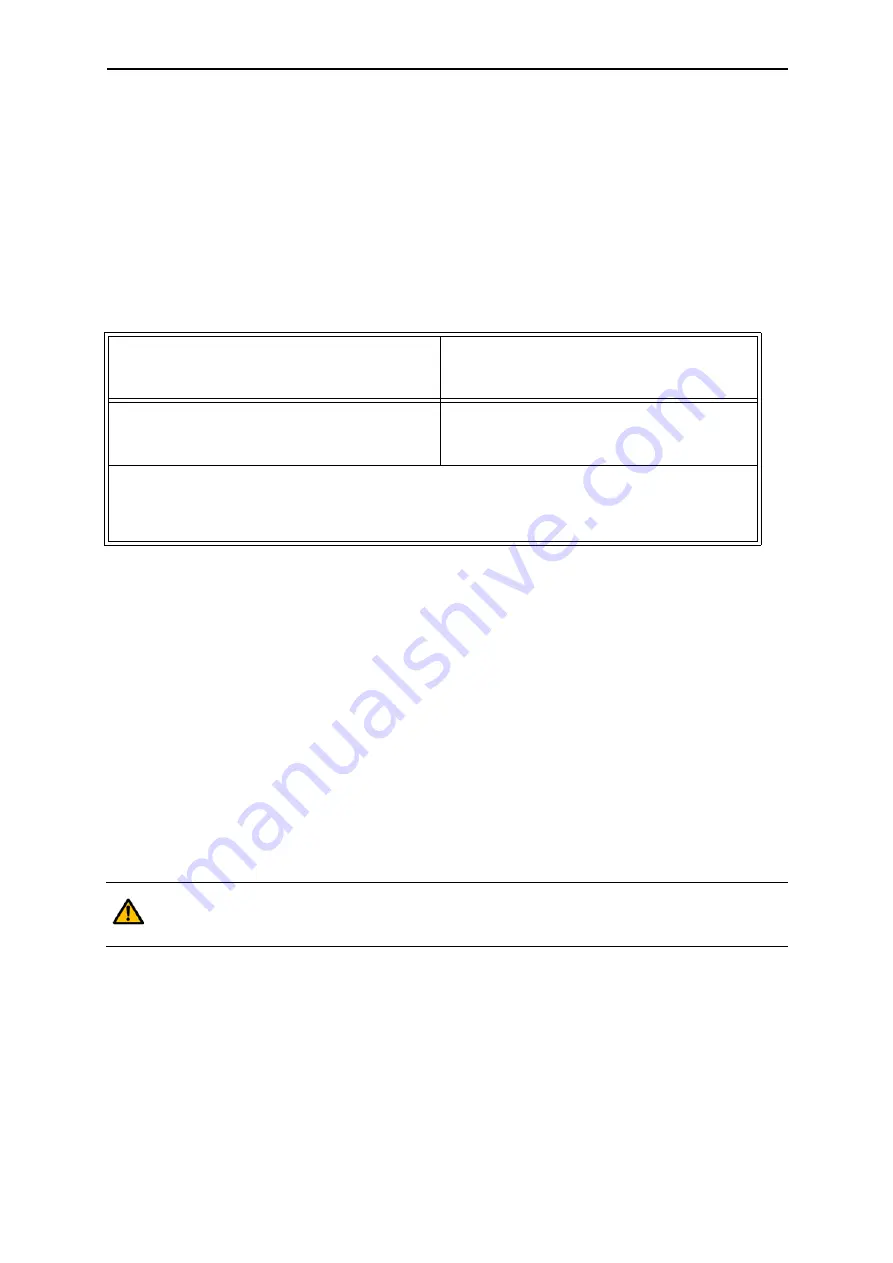

Table 2. Protective earthing conductor cross-section

The cross-sectional area of every protective earthing conductor which does not form a part of

the supply cable or cable enclosure shall, in any case, be not less than

•

2.5 mm

2

if mechanical protection is provided or

•

4 mm

2

if mechanical protection is not provided. For cord-connected equipment, provi-

sions shall be made so that the protective earthing conductor in the cord shall, in the

case of failure of the strain-relief mechanism, be the last conductor to be interrupted.

However, always follow the local regulations for the minimum size of the protective

earthing conductor.

NOTE:

Due to the high capacitive currents present in the drive, fault current protective switches

may not function properly.

1.4

EMC levels

SmartDrive HVAC inverters are divided into three classes according to the level of electromag-

netic disturbances emitted, the requirements of a power system network and the installation

environment (see below). The EMC class of each product is defined in the type designation

code.

Category C1 (Honeywell EMC class C):

Inverters of this class comply with the requirements

of category C1 of the product standard EN 61800-3 (2004). Category C1 ensures the best EMC

Cross-sectional area of phase conductors (

S

)

[mm

2

]

Minimum cross-sectional area of the corre-

sponding

protective earthing conductor

[mm

2

]

S

16

16

S

35

35 <

S

S

16

S

/2

The values above are valid only if the protective earthing conductor is made of the same metal as

the phase conductors. If this is not so, the cross-sectional area of the protective earthing conductor

shall be determined in a manner which produces a conductance equivalent to that which results

from the application of this table.

Do not perform any voltage withstand tests

on any part of the drive. There is a

certain procedure according to which the tests shall be performed. Ignoring this

procedure may result in damaged product.