10

EC7830, RM7830A,EC7850A,RM7850A 7800 SERIES RELAY MODULES

66-1092—2

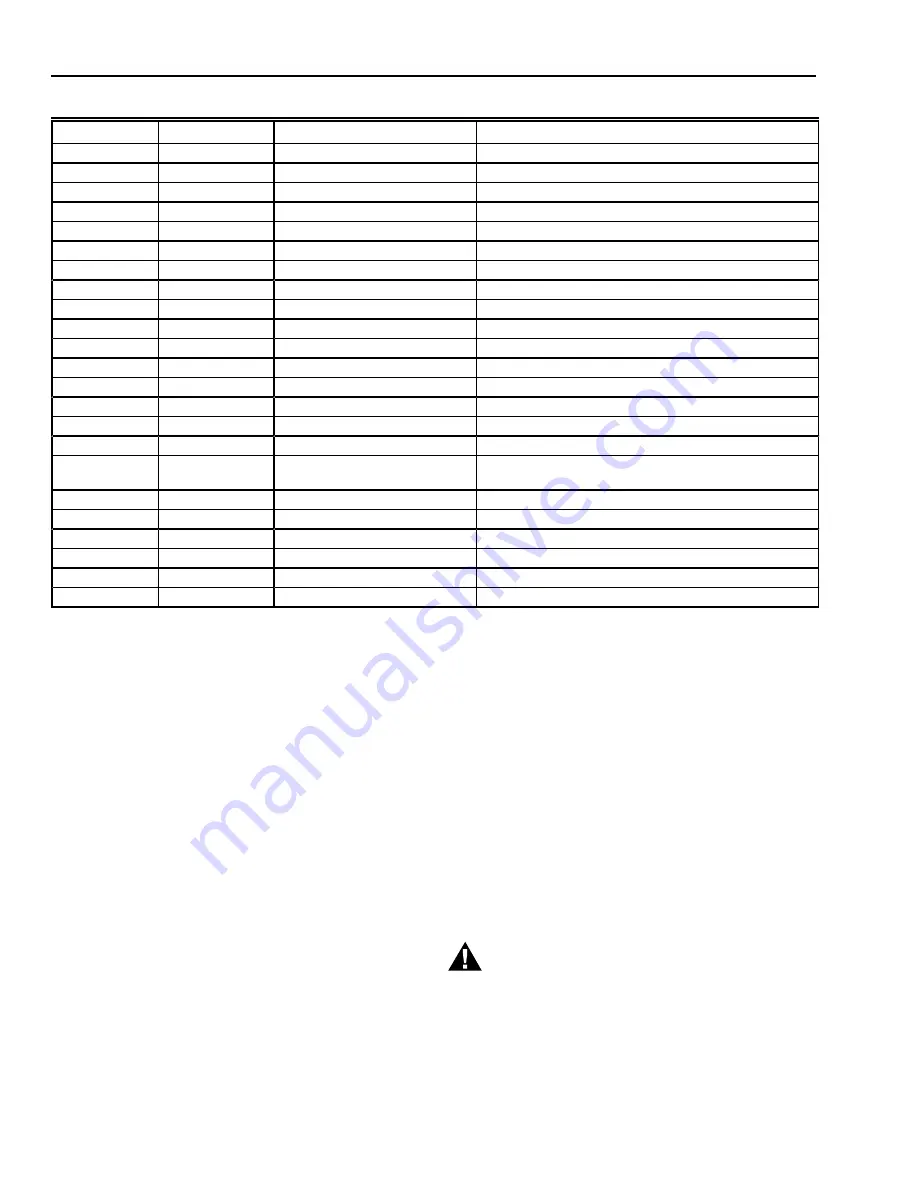

Table 3D. EC7850A Terminal Ratings.

a

See Table 2.

b

2000 VA maximum connected load to relay module.

c

Total load current, excluding Burner/Boiler Motor and Firing Rate Outputs cannot exceed 5A, 25A inrush for 250,000 cycles.

d

Can also be 24 Vac, 3A at PF = 0.5.

e

220/240 Vac to 120 Vac, 10 VA stepdown transformer (not provided) must be used to drive the shutter.

Mounting EC/RM7830A;

EC/RM7850A Relay Module

1. Mount the relay module vertically on the Q7800

Subbase, or mount horizontally with the knife blade

terminals pointing down. When mounted on the

Q7800A, the relay module must be in an electrical

enclosure.

2. When mounting in an electrical enclosure, provide

adequate clearance for servicing, installation and

removal of the relay module, KDM, flame amplifier,

flame amplifier signal voltage probes, electrical signal

voltage probes and electrical connections.

a.

Allow an additional 2 in. (51 mm) below the relay

module for the flame amplifier mounting.

b.

Allow an optional 3 in. (76 mm) minimum on both

sides of the relay module for electrical signal

voltage probes.

3. Make sure no subbase wiring is projecting beyond the

terminal blocks. Tuck in wiring against the back of the

subbase so it does not interfere with the knife blade

terminals or bifurcated contacts.

IMPORTANT

Install the relay module with a plug-in motion rather

than a hinge action.

4. Mount the relay module by aligning the four L shaped

corner guides and knife blade terminals with the

bifurcated contacts on the wiring subbase and securely

tightening the two screws without deforming the plastic.

STATIC CHECKOUT

After checking all wiring, perform this checkout before

installing the relay module on the wiring subbase. These tests

verify that the Q7800 Wiring Subbase is wired correctly and

the external controllers, limits, interlocks, actuators, valves,

transformers, motors and other devices are operating

properly.

WARNING

Fire or Explosion Hazard.

Can cause property damage, severe injury

or death.

Close all manual fuel shutoff valves before starting

this test to prevent an explosion.

Terminal No.

Abbreviation

Description

Ratings

G

Flame Sensor Ground

a

Earth G

Earth Ground

a

N

Line Voltage Common(Neutral)

3

AL

Alarm (Normally Open)

220/230/240 Vac, 1A, 10A inrush for 5000 cycles.

4

L1

Line Voltage Supply (L1)

220 to 240 Vac (+10/-15%), 50/60 Hz (

±

10%).

b

5

FAN

Burner/Blower Motor

220/230/240 Vac, 4A at PF = 0.5, 20A inrush.

6

RT

Limits and Burner Control

220/230/240 Vac, 1 mA.

7

LD2

Airflow Switch Input

220/230/240 Vac, 5A.

8

PV1

Pilot Valve 1 (Interrupted)

220/230/240 Vac, 4A at PF = 0.5, 20A inrush.

c

9

M V

Main Fuel Valve

220/230/240 Vac, 4A at PF = 0.5, 20A inrush.

c

10

IGN

Ignition

220/230/240 Vac, 2A at PF = 0.2.

c

F(11)

Flame Signal

136 to 220 Vac, current limited.

12

HI

Firing Rate High Fire

220/230/240 Vac, 0.5A at PF = 0.5.

d

13

COM

Firing Rate Common

220/230/240 Vac, 0.5A at PF = 0.5.

d

14

MOD

Firing Rate Modulate

220/230/240 Vac, 0.5A at PF = 0.5.

d

15

LO

Firing Rate Low Fire

220/230/240 Vac, 0.5A at PF = 0.5.

d

16

Alarm (normally closed)

220/230/240 Vac, 1A, 10A inrush for 6000 cycles;

carry 5A for 250,000 cycles.

17

ES2

Preignition Interlock Input

220/230/240 Vac, 1 mA.

18

ES1

Low Fire Switch Input

220/230/240 Vac, 1 mA.

19

ES3

High Fire Switch Input

220/230/240 Vac, 1 mA.

20

LOS

Lockout Input

220/230/240 Vac, 1 mA.

21

PV2

Pilot Valve 2 (Intermittent)

220/230/240 Vac, 4A at PF = 0.5, 20A inrush.

c

22

SHTR

Shutter

Shutter drive for dynamic self-check flame sensor.

e