C7012A,C,E,F,G SOLID STATE PURPLE PEEPER® ULTRAVIOLET FLAME DETECTORS

7

60-2398-17

NOTE: If you use 118367A Swivel Mount and you are

positive about the location and sighting angle, you

can permanently weld the pipe.

Install Fittings

In some cases, the sight pipe will not directly fit the C7012

mounting flange or union. Also, it may be desirable or

necessary to ventilate the sight pipe. You may also want to use

a swivel mount or an antivibration mount. Each of these cases

can require additional fittings.

Reducer

For sight pipes of larger diameter than the mounting flange

connector or union, install a reducer as illustrated in Fig. 5. The

reducer requires a close nipple with these external threads:

C7012A or E: 3/4 or 1 in. NPT (depending on model).

C7012C or F: 1 in. NPT.

C7012G: 3/4 in. NPT.

Sight Pipe Ventilation (C7012A,E, or

G)

It may be necessary to ventilate the sight pipe to cool the

detector or to clear a viewing path through UV radiation

attenuating material.

For a negative pressure combustion chamber, drilling a few

holes in the section of the sight pipe outside of the combustion

chamber allows air at atmospheric pressure to flow through the

sight pipe and into the chamber. A perforated pipe nipple

between the sight pipe and the detector can also be used.

For a positive pressure combustion chamber, connect a supply

of pressurized air from the burner blower to flow through the

sight pipe and into the chamber. The air pressure must be

greater than the chamber pressure.

Antivibration Mount (C7012A,E, or G)

The detector can withstand normal burner vibration. If the

vibration is excessive, part no. 123539 Antivibration Mount is

available for a C7012A,E or G. (For mounting details, see form

60-0361.) If you use this mount, install it before positioning and

sighting the detector.

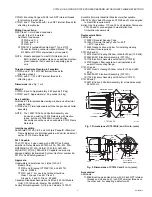

Mount the Detector (Fig. 5-8)

Mount the detector onto the sight pipe, reducer, or other fitting

(see Fig. 5-8).

The C7012A,C,G Flame Detectors do not have the oscillating

shutter mechanism for checking the UV sensor so they can be

mounted in any position suitable for the temperature

environment.

The C7012E,F Self-Checking Flame Detectors incorporate an

oscillating shutter mechanism and, therefore, require special

consideration for mounting positions other than vertically

sighting downward or upward. The C7012E has notch and

arrow indicators (see Fig. 6) on the faceplate to facilitate

mounting. The notch and arrow must be vertically aligned with

the notch in the up position and the arrow pointing downward

(see Fig. 6). The C7012F must be mounted with the conduit

opening located approximately 45 degrees below the

horizontal (see Fig. 6).

Fig. 6. C7012E,F mounting positions.

IMPORTANT

The notch and arrow on the faceplate of the C7012E

must be aligned in a

vertical

plane with the notch

up

and the arrow pointing

downward

.

The C7012F housing

must

be mounted with the

conduit opening approximately 45°

below horizontal

(see Fig. 6).

To mount a C7012A,E or G (Fig. 7):

1.

The mounting flange has two pieces. Loosen (but do not

remove) the three screws holding the flange together.

2.

Slightly rotate the detector so the slots in the back

section of the mounting flange clear the screws in the

front section; then separate the two sections.

3.

Screw the front section of the mounting flange onto the

sight pipe, reducer, or other fitting.

4.

Fit the slots in the back section of the mounting flange

(with the detector) over the three screws in the front sec-

tion, and rotate the detector so the screws hold the

flange together.

5.

Tighten the screws securely.

M6816

C7012E, F CAN BE MOUNTED

HORIZONTALLY, VERTICALLY, OR

AT ANY ANGLE IN BETWEEN

HORIZONTZAL

PLANE

VERTICAL

PLANE

90

90

1

1

1

NOTCH IN FACEPLATE

MUST BE UP

HORIZONTZAL

PLANE

NOTCH AND ARROW

MUST ALWAYS BE

ALIGNED IN A

VERTICAL PLANE

C7012E OR F

MUST NOT

BE ROTATED

AROUND

ITS AXIS

ARROW ON FACEPLATE

MUST BE POINTING

DOWNWARD

45

C7012F CONDUIT

OPENING POSITION

ADE IN U.S.A.

MOUNT WITH

ARROW DOWN

1

NOTE DOWNWARD

POSITIONING OF

CONDUIT OPENING.