MP953A,B,C,D PNEUMATIC ACTUATORS

EN0B-0552GE51 R1210

2

FEATURES

Rolling diaphragm for long life and low hysteresis

Easily attached to valve assembly

May be installed after valve piping

Slide lock feature permits simple engagement to valve

stem

Models with positive-positioning relay available

ACCESSORIES

Extension Yokes

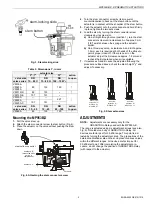

The extension yoke (see also Fig. 7) provides for extra air

circulation and less conduction of heat from the valve body to

the pneumatic actuator.

Recommended if the medium temperature in the valve body

is in the range of from 150 to 220 °C.

Table 3. Extension yokes

part no.

applied to valves

V5049A DN

15…65

V5050A DN

15…80

PN 25/40

V5025A

DN 15…80

PN 25

V5016A DN

15…80

V5328A

V5329A

DN 40…80

PN 16

43161276-001

V5329C

DN 40…80

PN 6

V5011R,S

V5013R,E

V5328A

V5329A

DN 15…32

PN 16

43297431-001

V5329C

DN 15…32

PN 6

Repair Kit Diaphragm

Table 4. Repair kit diaphragms

part no.

model

R43312760-001

MP953A,C 125 (5")

R43161319-001

MP953A,C 200 (8")

R43161320-001

MP953A,C 330 (13")

R43180626-001 (diaphragm. a. sleeve

MP953B,D 180 (7")

R43161322-001 (sleeve)

MP953B,D 180 (7")

TYPICAL OPERATION

In a direct-acting (normally-open valve) system, an increase

in control air pressure will force the actuator diaphragm and

cup downward, forcing the valve stem down to proportionally

close off the flow through the valve.

Operators without the positive positioner have branch line

pressure applied to the diaphragm. Operators with positive

positioners have up to full main air pressure applied to the

diaphragm to ensure that the valve is positioned

proportionally to the branch line pressure.

control air

valve

stem

flow

Fig. 2. Typical operation

INSTALLATION

General

Ensure that the actuator has the correct size and travel to

match the valve body. Refer to the corresponding valve

product literature.

Mounting the MP953A,C (Size 5")

1.

Pull the valve stem up.

2.

Position the stem-locking slide so that the large hole is in

view (see also Fig. 3).

3.

Set the actuator on the valve bonnet. Ensure that the stem

button passes through the hole in the stem-locking slide

and that the actuator is down flush on the shoulder of the

valve bonnet.

4.

Rotate the actuator on the valve bonnet to the desired

position and tighten both actuator set screws.

5.

Apply air pressure until the diaphragm cup contacts the

stem button and secure the stem button with the stem-

locking slide.

Mounting the MP953A,C (Size 8" and 13")

1.

If converting from smaller-size actuator, remove the

actuator by following, in reverse order, the steps outlined

in section "Mounting the MP953A,C (Size 5")".

2.

Remove the stem button (see also Fig. 5).

3.

Screw the stem button on the (single or double) stem

extension until it bottoms.

4.

Screw the stem extension on the stem until it bottoms

(flats or locking-pin hole provided).

5.

Rotate the stem extension as required to adjust dimension

"Y" as per Table 5 to the value listed, then lock the stem

extension in place by tightening the hex nut.