EN2C-0112SZ20 R0202

4

Technical Data

Housing

•

impact-proof, heat-resistant synthetic material

Colour: black

Drive motor

•

reversible synchronous motor

Switch point setting

•

stepless cam setting, lever-operated or spindle-driven

cams;

if spindle-driven, with superimposed scale

Position indicator

•

scale

Connection system

•

terminal blocks

Gearing

•

spur gearing, maintenance-free

Drive shaft

•

steel

Fitting and fastening

•

Fastened from inside via tapped M 5 through-holes

Diagram Shaft

Drive

Load torque

Holding

Voltage

Type

Remarks

time

torque

Nr.

Nr.

s

Nm

Nm

V

S1

5

5

2,5

0,8

230

LKS 160-02

B 5-5 S1

standard version

S2

5

5

2,5

0,8

230

LKS 160-04

B 5-5 S2

standard version

S1

5

3

1,5

0,6

230

LKS 160-08

B 5-3 S2

S1

5

5

2,5

0,8

230

LKS 160-10

B 5-5 S1

S2

5

3

1,5

0,6

230

LKS 160-12

B 5-3 S2

S6

5

34

3

3

230

LKS 160-18

B 5-5 S2

S2.1

5

5

2,5

0,8

230

LKS 160-19

B 5-5 S2.1

Shaft with adapter

S3.2

5

5

2,5

0,8

110

LKS 160-28

B 5-5 S3.2

S4

5

5

2,5

0,8

230

LKS 160-36

B 5-5 S4

S13

6

34

3

3

230

LKS 160-43

B 6-34 S13

Spindle-driven cam

S2

5

12

3

1,5

230

LKS 160-50

B 5-12 S2

S4

5

5

2,5

0,8

230

LKS 160-51

B 5-5 S4

S2

5

8

3

1,5

230

LKS 160-52

B 5-8 S2

Other cam colours

S8.P1

5

12

3

1,5

230

LKS 160-57

B 5-12 S8.P1

Potentiometer can be retrofitted

S4

5

12

3

1,5

230

LKS 160-60

B 5-12 S4

S6

5

5

2,5

0,8

230

LKS 160-61

B 5-5 S6

S8.P1.1

5

34

3

3

230

LKS 160-69

B 5-34 S8.P1.1

S6.1

5

5

2,5

0,8

110

LKS 160-71

B 5-5 S6.1

S4.9

5

5

2,5

0,8

230

LKS 160-74

B 5-5 S4.9

Relays control 24 VDC

S6.2

5

65

3

3

230

LKS 160-76

B 5-65 S6.2

S8.P1

5

5

2,5

0,8

230

LKS 160-77

B 5-5 S8.P1

Potentiometer can be retrofitted

S12

5

30

3

3

230

LKS 160-78

B 5-30 S10

Face down

counter-clockwise rotation

3 )

4 )

6 )

5 )

2 )

1 )

7 )

Legend

1) when viewing from direction A (see dimensional drawing)

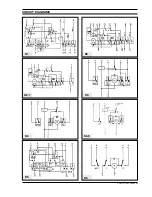

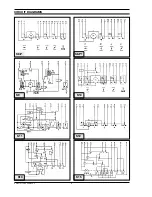

2) see “Circuit diagrams”

3) see “Dimensional drawing”

4) at 50 Hz for 90

°

at 60 Hz, Drive times are about 20 % shorter

5)

under nominal conditions

under extreme conditions (e.g. +60

°

C, 230V -15%) the torques will be 25% lower

6)

+10% -15%; 50...60Hz

at -15%; torque reduced by approx. 20% at undervoltage

7)

Standard: Lever-operated cam

PCBs

•

for all electrical functions, increased conductor thickness

Mains voltage

•

230 V -15% +10% or

110 V -15% +10%

Mains frequency

•

50 Hz or 60 Hz

Safety class

•

II VDE 0631

Power consumption

•

approx. 4 VA

Duty cicle

•

depending on motor, 50 to 70 % in 2 minutes

Interference suppression

•

N (according to VDE 0785)

Actuating angle

•

max. 90

°

Mounting position

•

any