GB-5

D

GB

F

NL

I

E

Adjustment

▷

The switching point is adjustable via hand wheel.

1

Disconnect the system from the electrical power

supply.

Detach the housing cover, see page 7 (Tech-

Connect an ohmmeter.

NO

2

NC

1

COM

3

COM

3

NC

1

NO

2

0

1 cm = 1 mbar

4

Set the switching point using the hand wheel.

5

Connect a pressure gauge.

NO

2

NC

1

COM

3

COM

3

NC

1

NO

2

0

1 cm = 1 mbar

6

Apply pressure. In doing so, monitor the switch-

ing point on the ohmmeter and the pressure

gauge.

Type

Adjusting

range*

[mbar]

Reset

pressure**

[mbar]

Max. inlet

pressure

p

max.

[mbar]

DG 10H,

DG 10N

1 – 10

0.4 – 1

600

DG 50H,

DG 50N

2.5 – 50

1 – 2

DG 150H,

DG 150N

30 – 150

2 – 12

DG 500H,

DG 500N

100 – 500

5 – 18

Type

Adjusting

range*

[mbar]

Switching

differential***

[mbar]

Max. inlet

pressure

p

max.

[mbar]

DG 1,5I

-1.5 to -0,5

and

+0.5 to +3

0.2 – 0.5

±100

DG 12I

-12 to -1

and

+1 to +7

0.5 – 1

±100

DG 18I

-2 to -18

0.5 – 1.5

±100

DG 120I -10 to -120

4 – 11

±600

DG 450I -80 to -450

10 – 30

±600

*

Adjusting tolerance = ± 15% of the scale value.

** Difference between switching pressure and pos-

sible reset.

*** Mean switching differential at min. and max. set-

ting.

▷

Deviation from the switching point during testing

pursuant to EN 1854:

Gas pressure switches: ± 15%.

Air pressure switches:

Deviation

DG..H, ..N, ..I

± 15%

DG 1,5I

± 15% or ± 0.4 mbar

DG 12I

± 15% or ± 0.5 mbar

DG 18I

± 15% or ± 0.5 mbar

▷

If the DG does not trip at the desired switch-

ing point, correct the adjusting range using the

hand wheel. Relieve the pressure and repeat

the process.

Tightness test

1

Shut off the downstream gas pipeline close to

the valve.

Open the valve and the gas supply.

▷

Check all used ports for tightness.

N

2

900 mbar

max. 2 bar

< 15 min

3

4

Maintenance

In order to ensure smooth operation: check the tight-

ness and function of the DG every year, or every six

months if operated with biogas.

▷

A function check can be carried out in case of

decreasing pressure control e.g. with the PIA.

▷

After carrying out the maintenance work, check

for tightness, see page 5 (Tightness test).

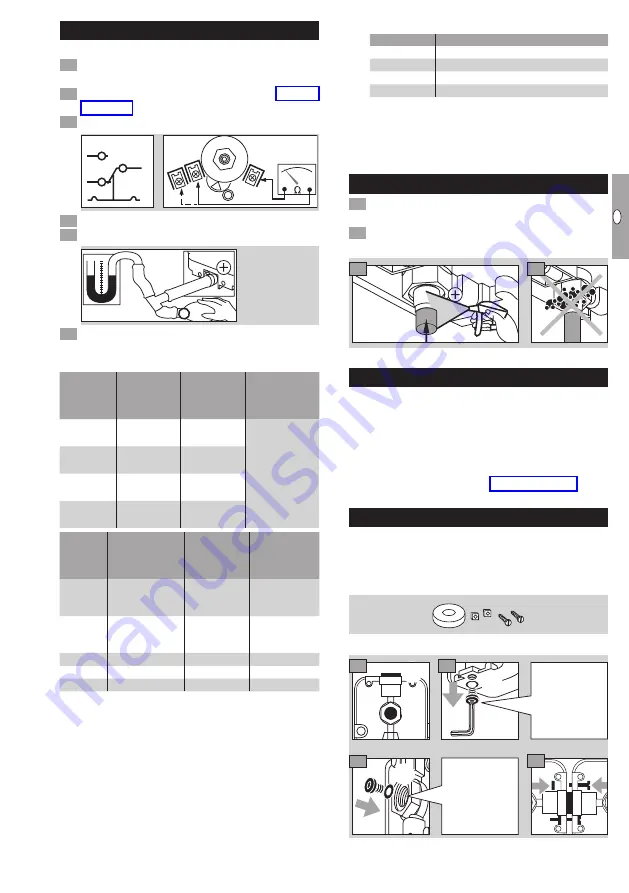

Accessories

Connecting set

For monitoring a minimum and maximum inlet pres-

sure p

u

with two pressure switches attached to one

another.

Order No.: 74912250

1

2

3

2

2

1

1

4

1

Remove from

both pressure

switches.

Install on one

pressure

switch.