Bump Test via DC

Apply gas from a cylinder to the sensors manually through the calibration cap, and using the

Device Configurator (DC) app on a mobile device.

1. Turn On the BW Flex Series. Wait a few minutes to sensors warm up.

2. In your mobile device, open the Detector Configurator app, and pair with the detector. For

details, go to See "Bluetooth Pairing" on page

3. In your mobile device, tap on the Menu button and then select Bump Test.

4. Enter the Operator Name, and then Tap Save. The IntelliFlash LED flashes amber to indicate

the bump test process has started.

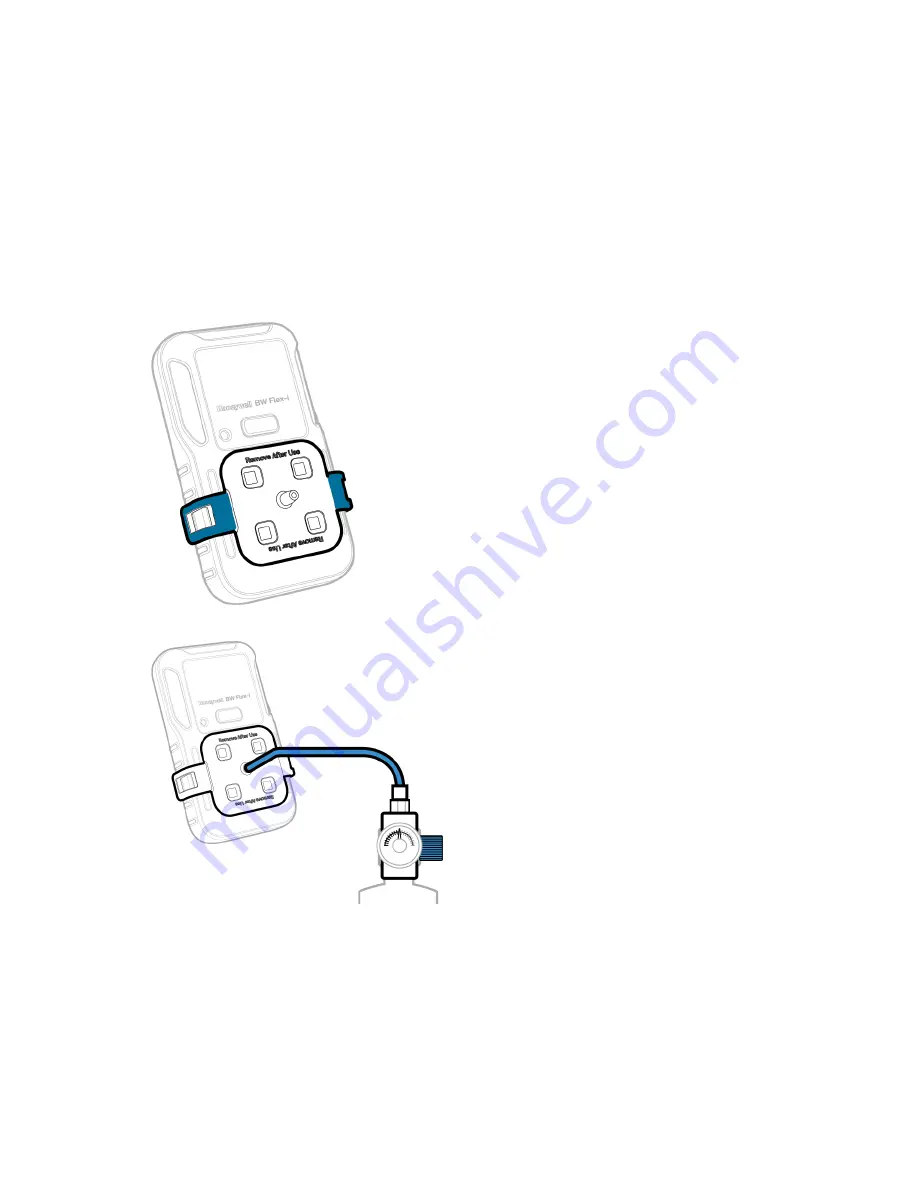

5. Place the cap over the detector, and then press down on both tabs to snap it into place. Wait

a few minutes to sensors warm up.

6. Attach the hose.

BW Flex Series

28

User Manual

Summary of Contents for BW Flex Series

Page 1: ...USER MANUAL Honeywell BW Flex Series Portable Multiple Gas Detector M05 4002 003 EN Rev A ...

Page 2: ......

Page 33: ......

Page 41: ......