6808 Manual — P/N LS10146-001SK-E:C 09/28/2017

83

Programming Overview

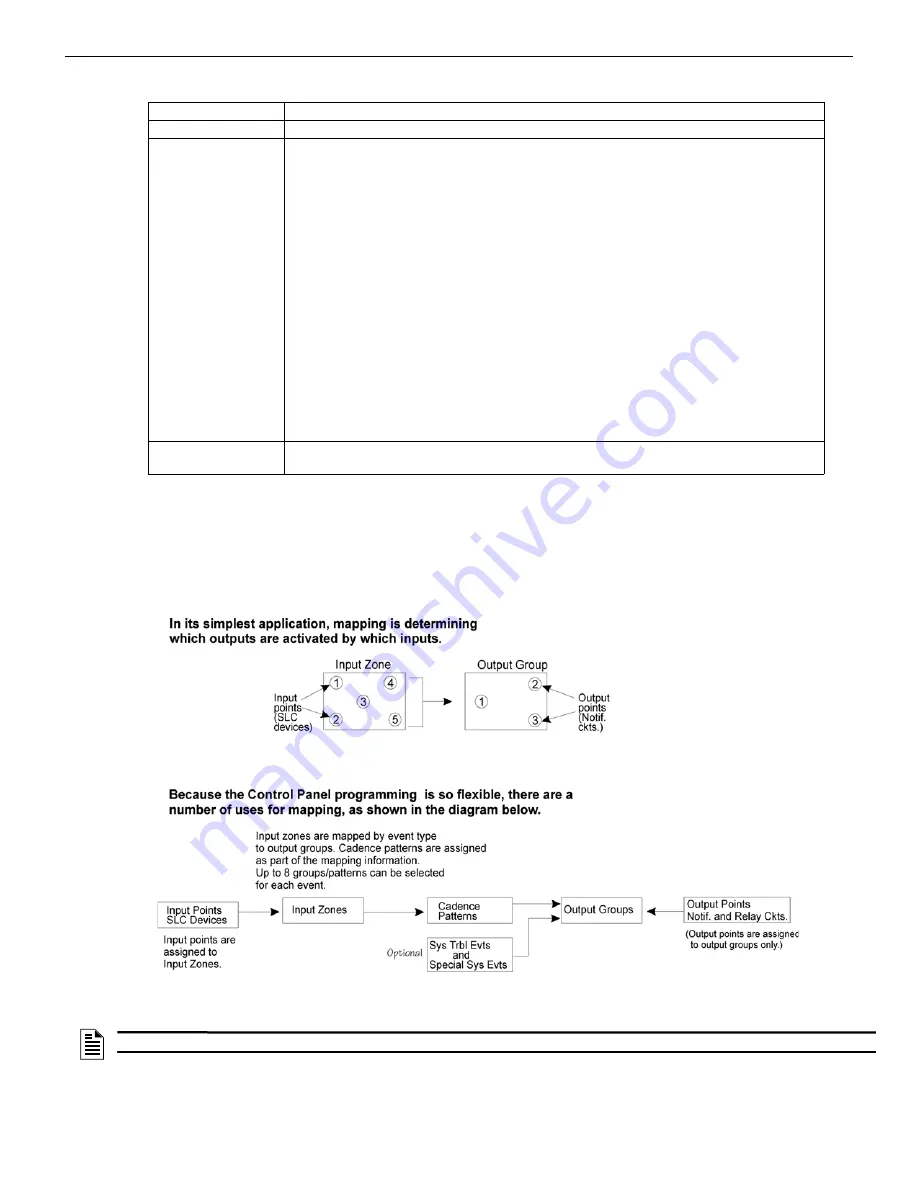

8.2 Mapping Overview

This section of the manual is an overview of mapping. Details about how to select mapping options appear in the appropriate subsections

in Section 9.

Mapping is an important concept with the control panel. In general terms, mapping is assigning or linking events to outputs that will acti-

vate when events occur. You do this by assigning input points to input zones, output points to output groups and then linking or mapping

zones and output groups.

Figure 8.1 is a brief overview of the concept of mapping. The next several pages of the manual show these subjects in detail.

Figure 8.1 Mapping Overview

1 - Review System

Press 1 if you need to review the JumpStart configuration.

2 - Repeat JumpStart

Press 2 if you need to rerun JumpStart for any reason.

3 - Accept Config.

1.

If you are ready to make the JumpStart configuration permanent, select 3.

2.

The system will ask you if the installation contains any Addressable Duct Detectors Used. If

there are none, select 2 for No and skip to Step 8. If the system contains duct detectors, select

1 for Yes and continue with Step 3.

3.

From the list that displays, select the SLC that contains the duct detectors.

4.

The first photoelectric or ionization detector on the system will display. Select 1 for DUCT and 2

for NonDUCT.

5.

Press up arrow to select the next detector. Select 1 for DUCT and 2 for NonDUCT. Continue

until all duct detectors have been selected. (Note: You can move backwards through the list with

down arrow).

6.

When you reach the last detector on this device, press left arrow.

7.

The system will ask you if there are any duct detectors used. If there are, select 1 for Yes and

the message will ask, Have All Addressable Duct Detectors Been Identified? Left arrow for “No”,

Right arrow for “Yes”. If there are no more duct detectors, continue with Step 8.

8.

The system will restart with the saved JumpStart configuration.

9.

After the system resets, it will use the new JumpStart configuration.

4 - Discard Changes

If you want to discard the changes, and keep the configuration you had before running this JumpStart

press 4.

NOTE:

Mapping cannot be programmed through annunciators and can only be programmed through HFSS Honeywell Fire Software Suite.

Summary of Contents for 6808

Page 13: ...6808 Manual P N LS10146 001SK E C 09 28 2017 13 Introduction ...

Page 67: ...6808 Manual P N LS10146 001SK E C 09 28 2017 67 Common Communication Link ...

Page 97: ...6808 Manual P N LS10146 001SK E C 09 28 2017 97 Programming Overview ...

Page 143: ...6808 Manual P N LS10146 001SK E C 09 28 2017 143 Testing and Troubleshooting ...

Page 159: ...6808 P N LS10146 001SK E C 09 28 2017 159 ...

Page 161: ...6808 P N LS10146 001SK E C 09 28 2017 161 ...

Page 163: ...6808 P N LS10146 001SK E C 09 28 2017 163 ...

Page 165: ...6820 6820EVS Manual P N LS10144 001SK E C 09 28 2017 165 ...

Page 168: ...Cut Along the Dotted Line ...

Page 169: ......