Servicing Your Honda

71

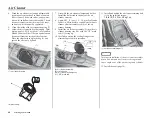

Throttle

1. Check that the throttle assembly is positioned

properly (the end of the throttle housing (1) is

aligned with the paint mark (2) on the

handlebar) and the securing bolts are tight.

2. Check for smooth rotation of the throttle (3)

from fully open to fully closed in all steering

positions. If there is a problem, see your dealer.

3. Inspect the condition of the throttle cables

from the throttle grip down to the throttle body.

If the cable is kinked or chafed, have it

replaced.

4. Check the cables for tension or stress in all

steering positions.

5. Lubricate the cables with a commercially

available cable lubricant.

Check for smooth rotation of the throttle. If

necessary, apply multi-purpose grease to sliding

surface of the throttle cable ends.

1. Slide the dust cover (1).

2. Remove the throttle housing bolts (2).

3. Remove the throttle housing (3) from the

throttle pipe (4).

4. Thoroughly lubricate the throttle cable ends (5)

with multi-purpose grease.

5. Install the throttle housing, then tighten the

throttle housing bolts to the specified torque:

7 lbf·ft (10 N·m, 1.0 kgf·m)

Align the lugs (6) of the wire guide with the

grooves (7) of the throttle housing.

6. Install the dust cover in the reverse order.

If the throttle operation is not smooth, replace the

throttle cable.

Be sure the throttle returns freely from fully open

to fully closed automatically, in all steering

positions.

Throttle Inspection

(1) throttle housing

(2) paint mark

(3) throttle

(2)

(1)

(3)

Throttle Cable Lubrication

(1) dust cover

(5) throttle cable ends

(2) housing bolts

(6) lugs

(3) throttle housing

(7) grooves

(4) throttle pipe

(5)

(2)

(1)

(3)

(6)

(4)

(7)

(7)

Summary of Contents for CRF450R 2020

Page 3: ...2020 Honda CRF450RX CRF450R CRF450RWE OWNER S MANUAL COMPETITION HANDBOOK ...

Page 19: ...14 Before Riding BLANK PAGE ...

Page 143: ...138 Servicing Your Honda BLANK PAGE ...

Page 175: ...170 Taking Care of the Unexpected BLANK PAGE ...

Page 189: ...184 Technical Information BLANK PAGE ...