Page 1

MAINTENANCE

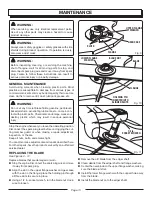

CLEANING THE AIR FILTER SCREEN

See Figures 1 - 1.

For proper performance and long life, keep the air filter

screen clean.

Remove the hex nut, wavy washer, flat washer, and choke

dial cover.

Brush the air filter screen lightly to clean.

Reinstall the choke dial cover, flat washer, wavy washer,

and hex nut. Tighten hex nut to secure.

FUEL CAP

WARNING:

A leaking fuel cap is a fire hazard and must be replaced

immediately.

The fuel cap contains a non-serviceable filter and a check

valve. A clogged fuel filter will cause poor engine perfor-

mance. If performance improves when the fuel cap is loos-

ened, check valve may be faulty or filter clogged. Replace

fuel cap if required.

SPARK PLUG

This engine uses a Champion RCJ6Y or equivalent spark

plug with .025 in. electrode gap. Use an exact replacement

and replace annually, or more frequently if necessary.

STORING THE PRODUCT

Clean all foreign material from the product. Store it in a

well-ventilated place that is inaccessible to children. Keep

away from corrosive agents such as garden chemicals

and de-icing salts.

Abide by all Federal and local regulations for the safe

storage and handling of gasoline.

WHEN STORING 1 MONTH OR LONGER:

Drain all fuel from tank into a container approved for

gasoline. Run engine until it stops.

Fig. 14

Fig. 15

HEx

NUT

FILTER

ScREEN

BRUSH

wAVY

wASHER

FLAT

wASHER

cHOkE DIAL

cOVER

FILTER

ScREEN

Summary of Contents for MIGHTYLITE UT50500

Page 21: ...NOTES ...