M&W-5

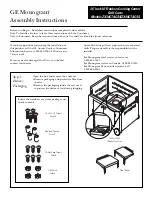

Step 4. MAVERICK & WRANGLER

Attach Grill Base to Grill Bottom Shell

Select the following parts for assembly:

1. grill bottom shell

3. heat shield

2. assembled grill base

A.

Select the heat shield and position it over the 4 bolt holes in the grill

base. Make sure the oblong opening in heat shield aligns with the

factory installed spark igniter and feed the wire through the hole.

B.

Position the assembled grill base on top of the heat shield.

IMPORTANT:

Route the gas hose and regulator through the opening

in the base pedestal before proceeding.

C.

Secure grill base assembly to the grill bottom shell using 4-1/4-20 x

1/2” Hex Head Bolts and lock washers. You might find it helpful to use

the phillips head screwdriver to help align the grill base, heat shield and

grill bottom shell holes. Tighten securely.

D.

Secure corner braces to the grill bottom shell using 4-1/4-20 x 1/2”

Hex Head Bolts and lock washers. Tighten securely. Now tighten the 4

Hex Head Bolts, lock washers and nuts that secure the corner braces

to the grill pedestal.

E.

Install the gas hose rubber grommet on the gas line into the

opening of the grill pedestal to protect from chaffing.

F.

Attach igniter wire to igniter control knob. Push firmly.

Step 5. MAVERICK & WRANGLER

Attach Grill Lid to Grill Bottom Shell

Select the following parts for assembly:

1. grill lid hinges (2 ea)

3. grill lid stops (2 ea)

2. thermometer

A.

Turn the assembled grill bottom and pedestal over so it now sits on

the four casters. Place the grill lid onto grill bottom assembly. Fasten

the two body hinges to the lid assembly using 8-1/4-20 x 1/2 Hex Head

Bolts and lock washers. Align the grill lid top with the grill bottom then

tighten all 8 hinge bolts completely.

B.

Select one of the lid stops. Insert the end of the lid stop with the slot

in it into the slot in the grill body bottom. Insert a T-Nut through slot in

lid stop. Insert 10-24 x 1/2 Phillips Head Screw with lock washer into

the hole in the grill bottom and screw it into the T-Nut. Tighten com-

pletely. Be sure that the T-Nut does not pinch the lid stop to the side of

the grill body. When the T-Nut is tight, the lid stop will move up and

down freely. Repeat for opposite side.

C.

Open lid just enough to insert lid stop into slot in lid end panel.

Then, insert a T-Nut through single hole in lid stop. Insert 10-24 x 1/2

Phillips Head Screw with lock washer into the hole in the lid and screw

it into the T-Nut. Tighten completely. Be sure that the T-Nut does not

pinch the lid stop to the side of the grill lid. The lid should move

smoothly when opened and closed. Repeat for opposite side.

D.

Install the thermometer through the three small holes in the center

of the lid. Using an adjustable wrench,

VERY GENTLY

, snug

thermometer securing nuts.

DO NOT OVERTIGHTEN

.

❍

❍

❍

❍

❍

❍

3A

3B

3C

4A

4B

4C

4D

4E

❍

❍

4F

❍

❍

Maverick & Wrangler