15

XL-LG20004UM-en-US Rev B · 2018-09-17 · Amendments and Errors Reserved · © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND, SAF,

and logos are trademarks of SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

Maintenance and Service Schedule

Table 1

Procedure

Interval

Notes

Landing Gear Inspection Every use

Replacement/repair required if

components visibly damaged,

loose, or broken.

Lubrication*

Every six (6)

months *Unless

No Lube

™

option selected.

More frequently in excessively

moist and dusty conditions, as

well as if not used for extended

periods of time.

Cleaning

With the vehicle

Hardware Inspection

Every 6 months

Landing Gear Alignment Every 6 months

Inspection required if landing

gear are visibly bent or damaged.

* DO NOT use lubrication containing Teflon.

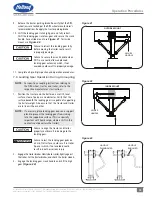

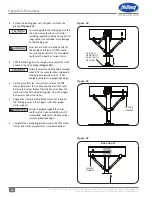

Figure 27

C

C

B

A

A

8. Routine Service and Inspection

8.1 Landing Gear Inspection (Before Use)

Before use, inspect the landing gear for cracks, bent components,

or damaged/missing hardware, and any noticeable defects.

The landing gear must be repaired prior to operation to avoid

damage and possible injury.

Failure to check the condition of landing

gear prior to operating could result in use

of damaged product which, if not avoided,

could result in death or serious injury.

8.2 Lubrication

The landing gear requires lubrication whether it is used

frequently or sits idle for extended periods of time. If left

idle and un-greased, hard cranking could result. Use high

quality grease for normal applications. For low temperature

applications, use low temperature grease. Follow these steps

to maintain expected performance

(Figure 27)

:

Failure to properly lubricate the landing

gear when required could result in

damage to the landing gear.

1. Place the trailer on level ground, chock the tires, and

support the trailer independently of the landing gear.

2. Fully retract the landing gear, then using high gear,

extend the leg 2-3 turns and lubricate the lift-screw

assembly through grease fitting “A”. Apply 1/2 lb.

of grease.

3. Lubricate the gearbox, using grease fitting “B”.

Apply 1/4 lb. of grease.

4. Lubricate the bevel gear, using grease fitting “C”.

Apply 1/4 lb. of grease.

5. Distribute the lubrication by fully extending and

retracting the leg several times.