BA_PH_245-20_EN_15-22.docx

48

14.4.2

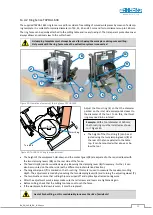

Ring Fence TAPOA 1639

The supplied TAPOA 1639 ring fence is used for accident-free milling of curved workpieces by means of a clamp-

ing template. It is suitable for spindle diameters of 30, 35, 40 and 45 mm and for tool diameters up to 160 mm.

The ring fence can be quickly attached to the milling table and is easy to adjust. The transparent protective cover

always allows an optimal view to the cutter head.

A clamping template must always be used for shaping the workpiece during curve milling.

Only work with the ring fence when the extraction system is connected.

Figure 39: Operation elements of the ring fence TAPOA 1639

Figure 40: TAPOA 1639 ring fence adjustment

Adjust the thrust ring (

1

) so that the diameter

printed on the inlet side corresponds closest to

the diameter of the tool. To do this, the thrust

ring may need to be rotated.

Example:

With a tool diameter of 140 mm,

the thrust ring must be installed as shown

in

•

The height of the thrust ring (

1

) can be ad-

justed using the two clamping levers (

9

) at

the rear of the fence parallel to the table

top. It can be mounted either above or be-

low the tool.

•

The height of the workpiece hold-down and the contact guard (

2

) are adjusted to the required level with

the two clamping levers (

10

) on the rear side of the fence.

•

The feed strip (

3

) can be swivelled away by loosening the clamping lever (

4

) if necessary. Further, it can

also be mounted on the other side (with a different spindle rotation direction).

•

The tangential point (

T

) is marked on the thrust ring. This mark is used to measure the maximum cutting

depth. The adjustment is made by loosening the two clamping levers (

5

) and turning the adjusting wheel (

7

).

•

The two brushes ensure that milling chips are wiped off and optimally extracted during work.

•

After the adjustment work, always make sure that all screws and levers are tightened again.

•

Before milling, check that the milling tool does not touch the fence.

•

If the workpiece hold-down is worn, it must be replaced.

Avoid climb milling, as this considerably increases the risk of accidents!

T

1

2

3

4

7

8

9

6

5

6

5

10

Ø 150

Turntable

Thrust Ring