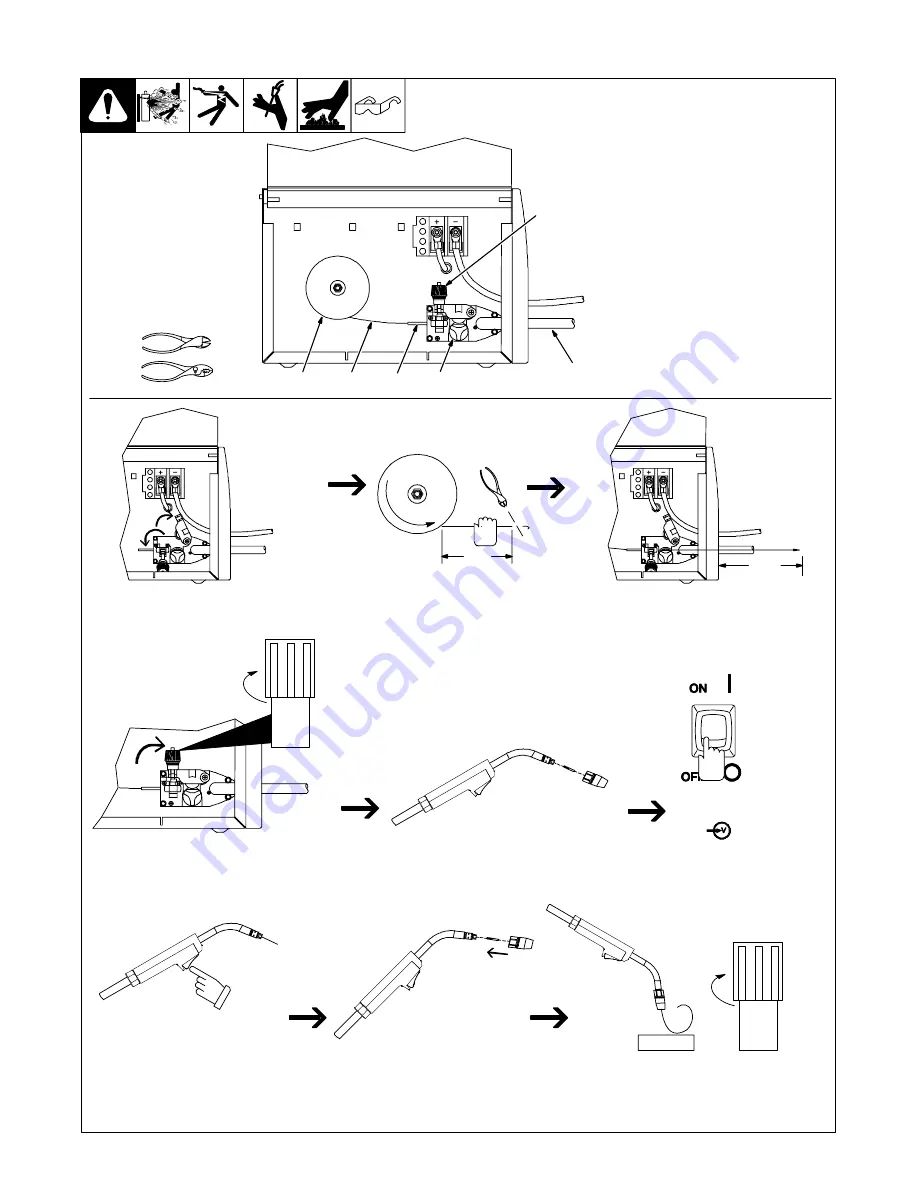

OM-948 Page 5

3-4.

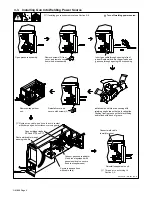

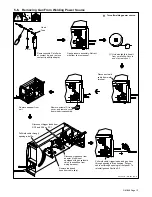

Threading Welding Wire

1

Wire Spool

2

Welding Wire

3

Inlet Wire Guide

4

Pressure Adjustment Knob

5

Drive Roll

6

Gun Cable

Lay gun cable out straight.

Tools Needed:

6

1

Pull and hold wire; cut off end.

4 in

(102 mm)

Remove gun nozzle and contact tip.

Open pressure assembly.

Push wire thru guides into gun liner;

continue to hold wire.

.

Hold wire tightly to keep it

from unraveling.

Ref. 803 444-A / Ref. 205 837

WOOD

Feed wire to check drive roll pressure.

Tighten knob enough to prevent slipping.

Cut off wire. Close door.

Press gun trigger until wire comes

out of gun.

2

Turn power on.

INPUT

POWER

6 in

(150 mm)

Tighten

.

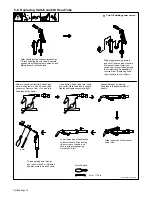

Rotate pressure adjustment

knob in a clockwise direction

until drive roll is tight against

the welding wire. Adjust

drive roll pressure just tightly

enough to prevent wire from

slipping on or against drive

roll during operation.

Tighten

Be sure that wire is positioned

in proper feed roll groove.

Close and tighten pressure

assembly, and let go of wire.

Be sure that contact tip matches wire diameter.

Reinstall tip adapter, if applicable, contact tip

and nozzle.

3

5

4

.

Tip adapter may also require removal

to allow wire to feed out end of gun.