5

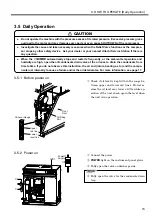

2.2 Main Component Units and their Functions

2. PARTS DESCRIPTION AND THEIR FUNCTIONS [Main Component Units and their Functions]

Air Dryer

This removes the mois-

ture in the compressed

air.

Cooling Fan Motor

Totally enclosed 4-pole

motor is used.

Cooling Fan

Squirrel cage fan is used

for cooling.

Oil Filter

This filtrates impurities

from lubricant.

Oil Separator

This separates lubricant

content from the com-

pressed air.

Minimum Pressure

/ Check Valve

This is found at the oil

separator's outlet and

regulate the minimum

pressure as 0.44 MPa or

over. By this action, the

valve prevent lubricant

from carryover due to in-

creased flow speed at low

pressure.

Air Intake Filter

This prevents foreign

bodies in the air from

being taken in the com-

pressor.

Relief Valve

This unlocks and re-

leases compressed air

when the inner pressure

of the separator abnor-

mally increases.

Oil Level Gauge

Oil Temperature

Control Valve

This retains the oil tem-

perature at the appropri-

ate level.

Suction Throttle Valve

This controls capacity of

air intake against load

fluctuation.

Driving Unit

This increases the revo-

lution of the main motor

with the help of a pulley

and a V-belt.

Air Discharge Duct

Oil cooler/Aftercooler

Assembly

Oil cooler and Aftercooler

are integrated into an as-

sembled unit, however,

the first cools lubricant

while the second cools

compressed air.

Main Motor

Totally enclosed, exter-

nal-fan cooled 4-pole

motor is used.

Starter

Oil Case

T h i s m a k e s p r i m a r y

separation of lubricant

content from the com-

pressed air, and its lower

part serves an oil sump.

Note: The figure shows the structure of 22 kW type.