--- 9 ---

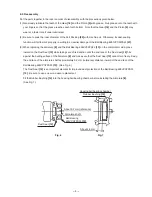

8-2. Reassembly

Put the parts together in the reverse order of disassembly, with the precautions given below.

(1) Generously lubricate the teeth of the Gear

[18]

and the Pinion

[5]

with grease. Rub grease onto the teeth with

your fingers so that the grease reaches each tooth bottom. Note that the Gear

[18]

and the Pinion

[5]

may

wear at a faster rate if under-lubricated.

(2) Be sure to soak the inner diameter of the Felt Packing

[22]

with machine oil. Otherwise, its dust-sealing

function will fail to work properly, resulting in an earlier damage of the Ball Bearing 6201VVCMPS2L

[21]

.

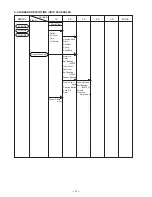

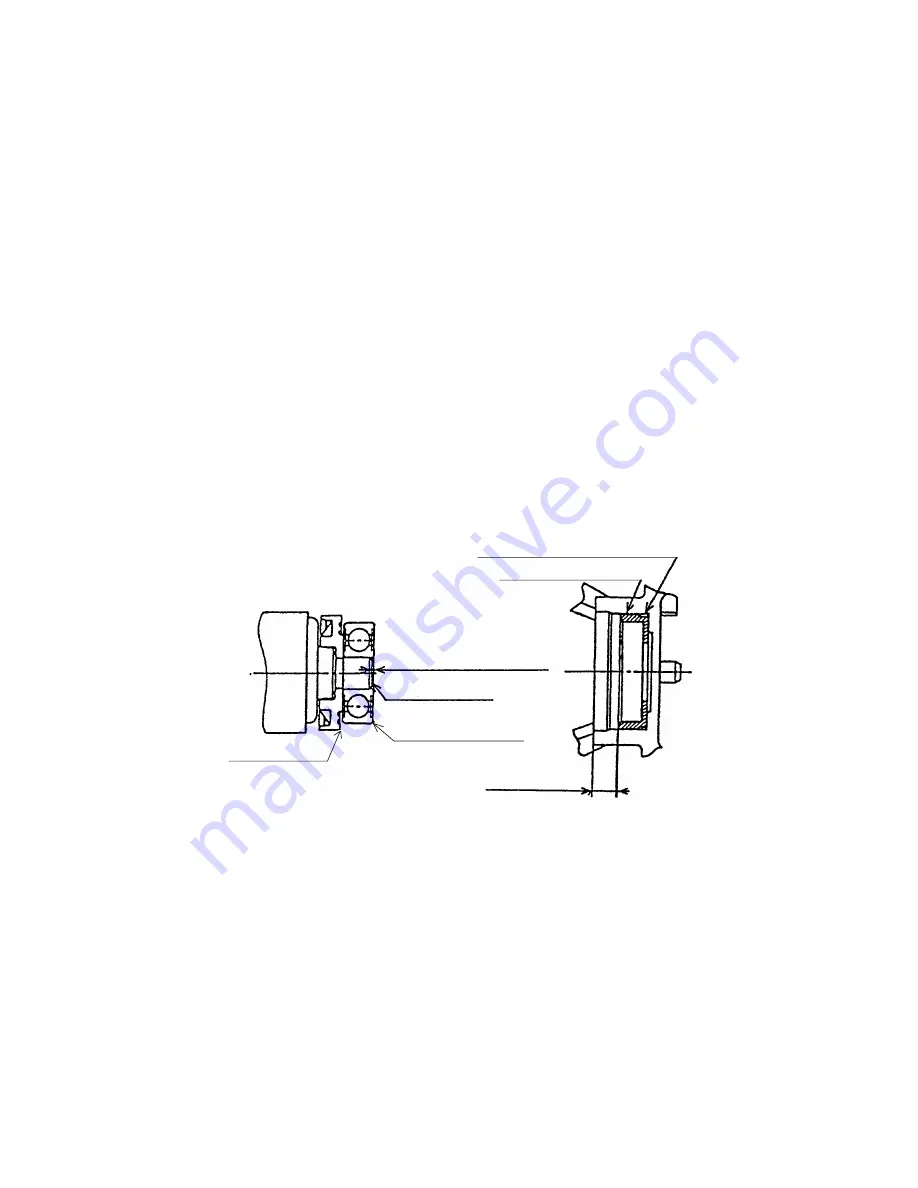

(3) When replacing the Armature

[8]

and the Ball Bearing 626VVC2PS2L

[13]

on the commutator side, press

inward on the Dust Seal

[12]

while taking care of its direction until the end face of the Dust Seal

[12]

hits

against the butting surface of the Armature

[8]

and make sure that the Dust Seal

[12]

cannot turn freely. Keep

the end face of the armature shaft approximately 0.2 mm (reference) distance inward of the end face of the

Ball Bearing 626VVC2PS2L

[13]

. (See Fig. 6.)

The Dust Seal

[12]

is an important element for improved dust protection of the Ball Bearing 626VVC2PS2L

[13]

. Be sure to use a new one upon replacement.

Fit the Rubber Bushing

[14]

into the housing ball bearing chamber before installing the Armature

[8]

.

(See Fig. 7.)

About 0.2 mm (reference)

Housing ball bearing chamber

Rubber Bushing

[14]

Armature shaft

Ball Bearing

626VVC2PS2L

[13]

Dust Seal

[12]

About 4.5 mm

Fig. 6

Fig. 7

Summary of Contents for G 13SR3

Page 30: ......