5.3 Installing the DSP Air Compressor

■

I

nstall the

DSP

in a bright, wide, and airy room as follows:

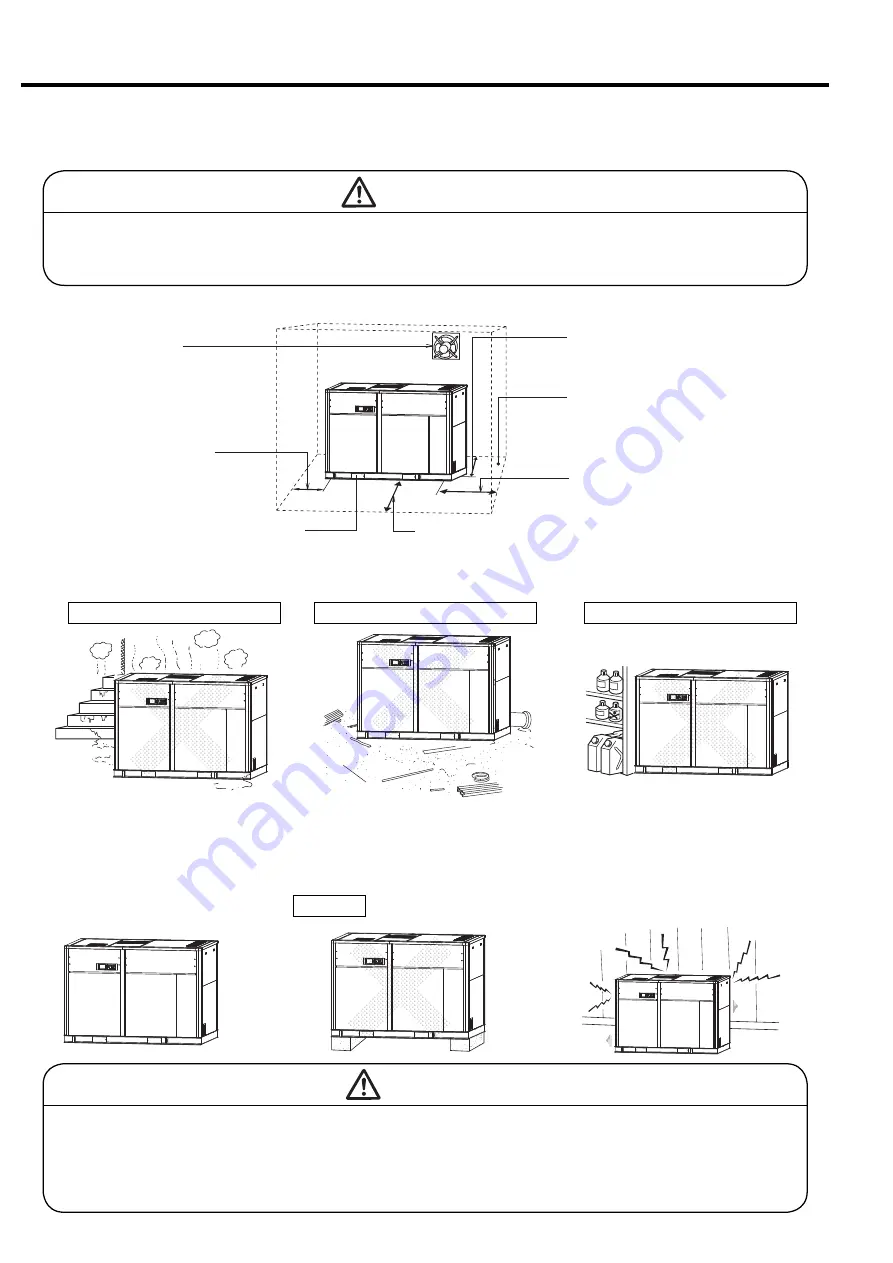

Piping and

Maintenance Space

Air Intake Maintenance Space

Maintenance Space

Maintenance Space

Keep a space of 1.0 m (39

inches) or more to connect

a plant airline pipe and

ease the maintenance

servicing.

Keep a space of 1.5 m (59 inches) or

more. Note that the air intake grill is

located on the rear enclosure panel.

Keep a space of 0.8 m (31 inches) or

more to connect the discharge

compressed air piping and for ease of

maintenance.

Keep a space of 1.5 m (59 inches) or

more to allow opening the front door.

Ventilating Fan

If you install the DSP in a

small room, provide a

ventilating fan to keep the

room temperature at 40

℃

(104

℉

) or lower.

Plug the fork slots with

the fork slot covers

(standard accessory)

Foundation

Provide a vibration-absorbing mat if

the foundation is vibrative. If it is too

vibrative, look for another dequate

location.

■

Install the

DSP

in a dry and dust-free room, and avoid the following.

■

I

nstall the

DSP

on a level floor.

■

Do not install the

DSP

near a wall. Doing

this may cause the operating sound to

resonate and increase the sound levels.

Raindrops, Basements, Steam

Metals, Sand, Other Hard Materials

Harmful Gases

Do not set the DSP

on the blocks.

( )

Chlorine, hydrogen sulfide, sulfurous acid, highly

concentrated ozone, and ammonium gases

38

5. INSTALLING AND PIPING THE DSP [Installing the DSP Air Compressor]

WARNING

1. Keep flammable solvents or any other hazardous chemicals away from the

DSP

. Such chemicals may be

sucked by the air end, compressed, and exploded.

2. Do not use fire near the

DSP

; otherwise the sparks may enter the air end and burn it internally.

Prohibited

CAUTION

●

Install the

DSP

indoors. Installing it outdoors may lead to a damage of the air end due to water vapor,

dust, etc.

●

The

DSP

installation room must have an air intake opening and an air exhaust opening and must be

well ventilated. If the room is poorly ventilated, hot air exhausted by the DSP may cause the room

temperature to rise abnormally and in the worst case lead to damage of the air end.

These conditions may cause leakage,

condensation, rusting and CPU mal-

function.

These conditions may cause deterio-

ration of motor insulation level, dam-

age to the air end bearings and CPU

malfunction.

These conditions may cause oil deterio-

ration, corrosion of coolers and peeling

of the rotor coatings.

Installing on a level floor is required to keep an

adequate amount of lubrication oil in the DSP

and prevent excessive noise and vibration.