--- 13 ---

Vibration of

the main body

Vibration of

the weight

Vibration of

the weight

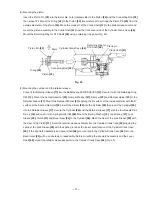

Fig. 5

Vibration of

the main body

Dynamic damper with leaf spring

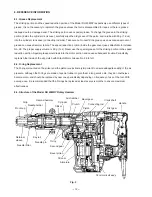

The vibration caused by hammering operation of the

Model DH 40MRY is transmitted to the cylinder crank

case, back cover, housing and finally to the weight

through the leaf spring supporting portion. Then the

weight moves in the reverse direction of the transmitted

vibration to negate the vibration of the main body (Fig. 4).

Fig. 4

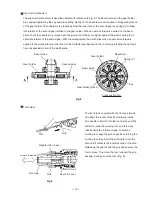

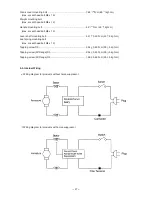

Cylindrical rubbers

(handle damper: 4 pcs.)

Cylindrical

convex

Handle damper

retaining material

(handle side)

Slotted

groove

Vibration-proof rubbers

Reaction

Pressing

force of the

main body

Main body side

The Model DH 40MRY has the vibration-proof handle

equipped with the transatory unit and the Neidhardt spring.

Structure of the transatory unit

The main body (cylinder crank case) is connected to the

upper handle through four cylindrical rubbers (handle

dampers). These rubbers are rolled and compressed on

the inclined surface to absorb vibration. Since the

transatory unit has nonlinear spring characteristics, the

spring constant is lower than the conventional shearing

type vibration-proofing structure. Thus the Model

DH 40MRY can provide high vibration-proofing effect with

good cushioning properties. The joint of the slotted groove

and the cylindrical convex is provided at the center to

prevent the handle from being pulled out by twisting or

pulling operation in the hammer mode (Fig. 5).

Handle damper retaining material

(Cylinder crank case)

Handle side

Rolled and compressed

(b) At full-load

(a) At no-load

Torque transmission

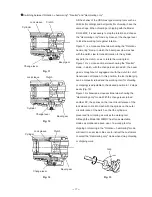

Armature revolution is transmitted to the second gear to rotate the bevel gear via the slip mechanism between

the second gear and the bevel pinion axes. Rotation of the bevel gear is then transmitted to the cylinder keyed

thereto through the clutch. Cylinder rotation is conveyed to the retainer sleeve coupled together by means of

four needle pins and, then to the drill bit inserted into the retainer sleeve by way of three key rails and two

needle rollers which couple them together.

Vibration-proof handle thanks to the transatory unit and the Neidhardt spring

Summary of Contents for DH 40MRY

Page 39: ......