12

English

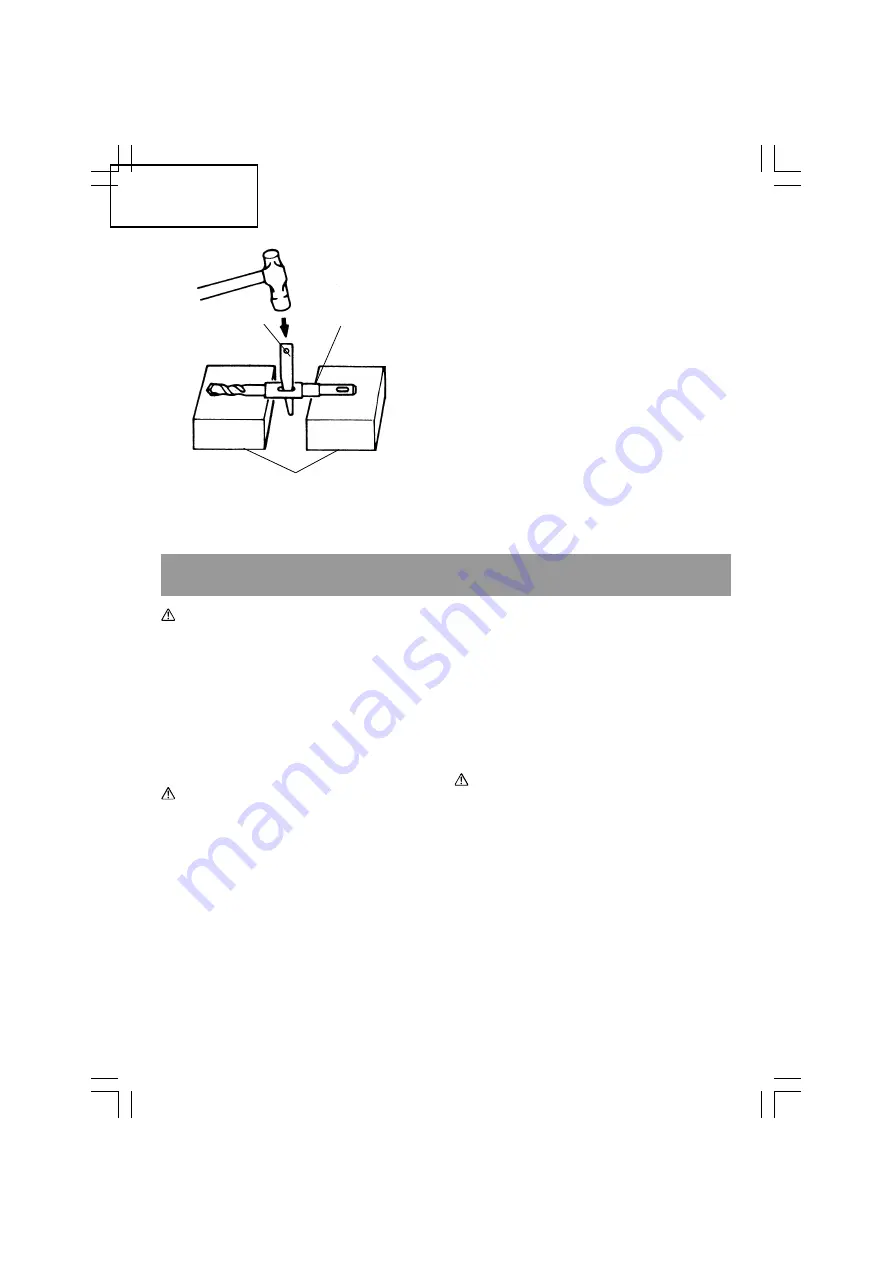

Cotter

Rests

Taper shank adaptor

Fig. 17

MAINTENANCE AND INSPECTION

WARNING: Be sure to switch power OFF and disconnect the plug from the receptacle during maintenance

and inspection.

1. Inspecting the drill bits

Since use of a dull tool will cause motor

malfunctioning and degraded efficiency, replace the

drill bit with a new one or resharpening without

delay when abrasion is noted.

2. Inspecting the screws

Regularly inspect all screws and ensure that they

are properly tightened. Should any of the screws

be loosened, retighten them immediately.

WARNING: Using this rotary hammer with

loosen screws is extremely

dangerous.

3. Maintenance of the motor

The motor unit winding is the very “heart” of the

power tool. Exercise due care to ensure the winding

does not become damaged and/or wet with oil or

water.

4. Inspecting the carbon brushes

For your continued safety and electrical shock

protection, carbon brush inspection and

replacement on this tool should ONLY be performed

by a Hitachi Authorized Service Center.

5. How to replace grease

Low viscosity grease is applied to this rotary

hammer so that it can be used for a long period

without replacing the grease. Please contact the

nearest service center for grease replacement when

any grease is leaking from loosened screw. Further

use of the rotary hammer despite the grease

shortage causes seizure to reduce the service life.

CAUTION: A specific grease is used with this

machine, therefore, the normal

performance of the machine may be

badly affected by use of other

grease. Please be sure to let one of

our service agents undertake

replacement of the grease.

6. Service and repairs

All quality power tools will eventually require

servicing or replacement of parts because of wear

from normal use. To assure that only authorized

replacement parts will be used, all service and

repairs must be performed by a Hitachi Authorized

Service Center, ONLY.

01Eng_DH22PH_US

1/22/09, 21:31

12