--- 4 ---

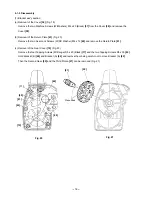

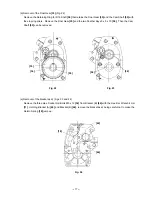

Cutter (1)

4th

3rd

2nd

1st

(4) Long service life through use of stud cutting edges

Because of the uniquely shaped cutters specially developed by HITACHI, each cutter has four (front, back, upper,

and lower) which can be used in turn for cutting studs. Each cutter is made of high wear-resistant, special steel,

and is capable of cutting up to 500 studs with each of its cutting edges. Accordingly, up to 2,000 studs can be cut

with appropriate use of the four cutting edges.

(5) Excellent working efficiency

In conventional cutting with a cut-off machine or disc grinder, considerable time is required for deburring after the

studs have been cut. In actual tests, the Model CL 10D2 is approximately three times more efficient than cut-off

machines or disc grinders.

Table 1. Cutting time comparison

Table 2. Number of studs that can be cut per battery charge

Fig. 9

Four cutting edges

Reverse cutters

by turning each,

top to bottom.

Cutter (2)

Reverse cutters

by turning each,

side to side.

Reverse cutter (1)

and cutter (2)

mounting positions.

Reverse cutters

by turning each,

top to bottom.

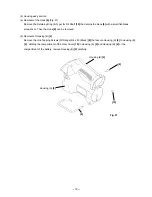

Type of cutting tool

Cordless stud cutter CL 10D2

Cordless stud cutter CL 10D

High-speed cut-off machine

Grinder

Hand saw

Cutting time

10

(sec.)

2.6 (M10)

2.4 (M10)

30 to 60

8

20

30

Stud size

M6

M8

W 3/8"

M10

Number of cuts per charge

EB 1230H

EB 12B

(Piece)

1270

850

850

570

550

370

620

410