--- 10 ---

8-3. Lubrication Points and Types of Lubricant

Anytime the Gear Cover [2] is disassembled, thoroughly clean out the old grease and insert 15 grams (.53 oz) of

new grease (Nippeko grease (SEP-3A) is recommended) prior to reassembly.

8-4. Tightening Torques

(1) Tapping Screws D5 x 30 [1] ................................................... 2.9 0.5 N

•

m (30 5 kgf

•

cm, 2.2 0.4 ft-lbs.)

(2) Tapping Screws (W/Flange) D4 [48] [51] .............................. 2.0 0.5 N

•

m (20 5 kgf

•

cm, 1.5 0.4 ft-lbs.)

(3) Hex. Socket Set Screw M8 x 20 [3] ....................................... 8.8 1.0 N

•

m (90 10 kgf

•

cm, 6.3 0.7 ft-lbs.)

(4) Brush Cap [41] ...................................................................... 1.0 0.5 N

•

m (10 5 kgf

•

cm, 0.7 0.4 ft-lbs.)

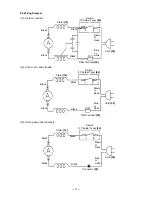

(6) When installing the Stator [14] into the Housing Ass'y [32], insert it while taking care of the placement of the

internal wires of the Stator [14] as indicated in Fig. 8. Connect the four internal wires of the Stator [14] with

the parts indicated in Fig. 8.

Connect to the Brush Holder [43]

(on the same side as the Name Plate [33]).

Connect the Cord [52] with the Pillar

Terminal [39].

Connect to the Switch (1P Solder Type) [44].

(When using the Noise Suppressor [36],

connect to the Switch (1P Solder Type) [44] with

the Terminal [46] of the Noise Suppressor [36].

Connect to the Brush Holder

[43] (on the same side as

the Hitachi Label [40]).

Fig. 8

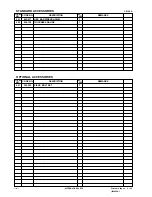

(7) When connecting the Earth Terminal [34] to the internal wire (the middle wire among three) of the Noise

Suppressor [36], strip the insulation sheath on the internal wire by about 6 mm and press-connect it together

with the Earth Terminal [34] with a clamping tool on the market.

Solderless connection

Fig. 9

Summary of Contents for CE 16SA

Page 21: ......