28

CP-RX78 ( C15-20EE )

By the control panel

By the remote control transmitter

1. Display the Advanced menu by

the “MENU” button.(If EASY

MENU appears, choose “Go to

Advanced menu” to display

ADVANCED MENU.)

2. Select the “OPTION” on the

menu.

3. Continue press the button [ ]

fi

rst, then press the button [ ]

together with “INPUT”, and hold

for 3 seconds.

1. Display the menu by the

“MENU” button. (If EASY

MENU appears, choose “Go to

Advanced menu” to display

ADVANCED MENU.)

2. Select the “OPTION” on the menu.

3. Press the “MAGNIFY OFF”

button.

Next hold the “MAGNIFY OFF”

button for 3 seconds.

To display the OSD for “HIDDEN SERVICE MENU” set up.

HIDDEN SERVICE

AIR-SENSOR

1

1234h

NORMAL

STARTUP TYPE

PANEL TIME

LONG KEY

SOFT RESET

EXECUTE

6-13 HIDDEN SERVICE MENU

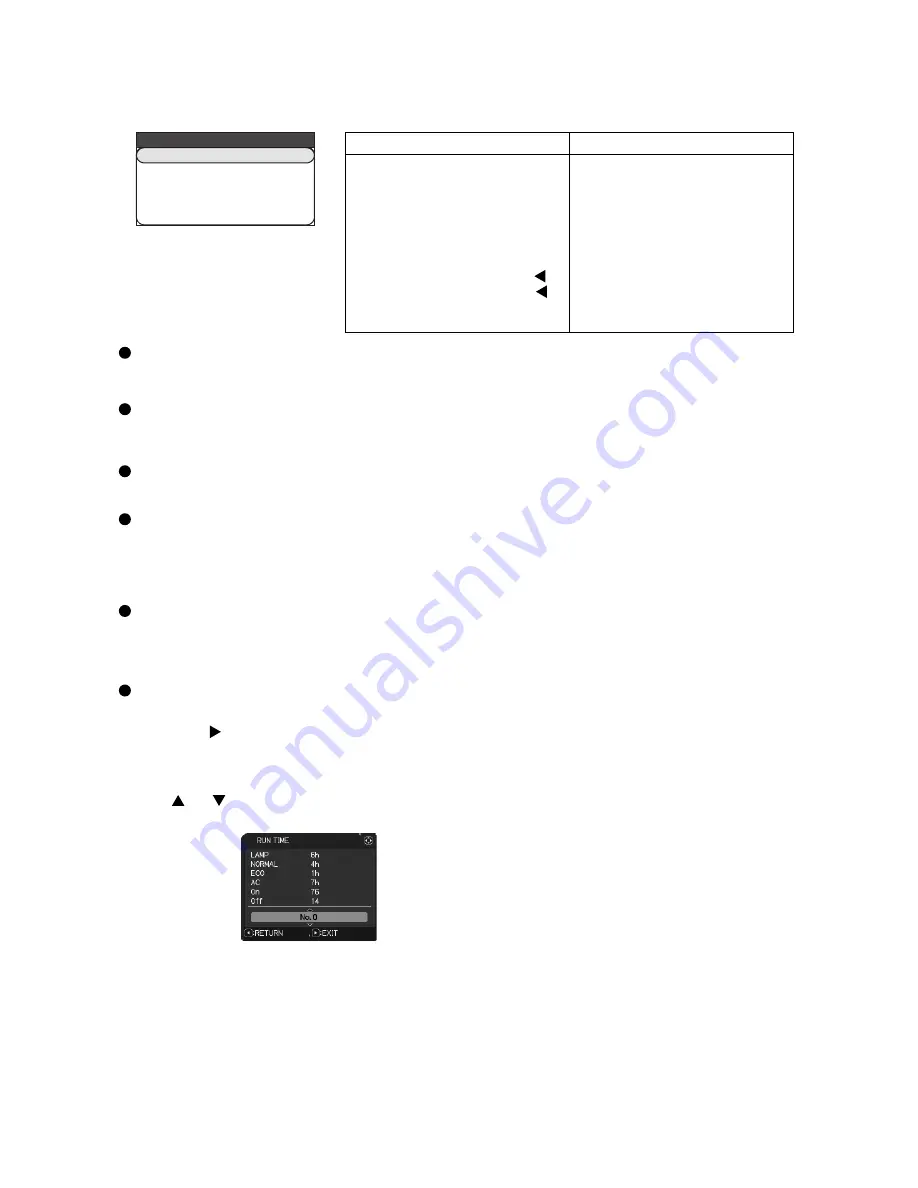

6-14 RUN TIME window

AIR - SENSOR

Execute this item to adjust the air sensor.

STARTUP TYPE

Select the startup screen type. 1 : shows Hitachi Logo

2 : No Hitachi Logo

PANEL TIME

Use time of LCD panel. Reset the PANEL TIME whenever you changed the LCD/LENS prism assembly panel.

LONG KEY

You can select the remote control button operation mode. NORMAR

↔

LONG

The LONG allows to control the projector with the remote control unit when you hold a button of it

for about 3seconds,

and makes MY BUTTON 1/2 function as LONG KEY DISABLE/LONG KEY ENABLE compulsorily. If you use

these buttons to control the projector as you assigned with the MY BUTTON menu, set to the NORMAL.

SOFT RESET

If this is executed, all of the user data is initialized.Never use it when not required.

Set operating time display method (accumulated lamp time display method)

1. Select “OPTION” from the Advanced menu, then place the cursor on the “LAMP TIME”.

2. Press the [ ], [ENTER] or [RESET] button.

3. Press the [Reset] button once, then press [KEYSTONE] button of the remote control for 3 seconds or

more to display the screen shown below. (The menu will close after 10 seconds if there are no further

operations.)

4. Use [ ] or [ ] to select the usage status number. (The usage status is as shown below.)

Usage status number

0 ..... Total usage status

1 ..... Current usage status

2 ..... Usage status before first reset

3 ..... Usage status before second reset

||

9 ..... Usage status before eighth reset

←

Lamp time

←

Lamp time ( Normal )

←

Lamp time ( ECO )

←

AC energizing time

←

Number of times on

←

Number of times off

←

Usage status number(See below)

Summary of Contents for C15-20EE

Page 46: ...46 CP RX78 C15 20EE 10 Block diagram VIDEO ...

Page 47: ...47 CP RX78 C15 20EE 11 Connector connection diagram ...

Page 49: ...CP RX78 C15 20EE 1 2 3 4 5 6 1 2 3 4 5 6 A B C D E F G POWER UNIT BALLAST 1 CONFIDENTIAL ...

Page 50: ...CP RX78 C15 20EE 1 2 3 4 5 6 1 2 3 4 5 6 A B C D E F G POWER UNIT BALLAST 2 CONFIDENTIAL ...

Page 51: ...CP RX78 C15 20EE 1 2 3 4 5 6 1 2 3 4 5 6 A B C D E F G POWER UNIT CIRCUIT CONFIDENTIAL ...

Page 52: ...CP RX78 C15 20EE 1 2 3 4 5 6 1 2 3 4 5 6 A B C D E F G PWB assembly MAIN 1 CONFIDENTIAL ...

Page 54: ...CP RX78 C15 20EE 1 2 3 4 5 6 1 2 3 4 5 6 A B C D E F G PWB assembly MAIN 3 CONFIDENTIAL ...

Page 55: ...CP RX78 C15 20EE 1 2 3 4 5 6 1 2 3 4 5 6 A B C D E F G PWB assembly MAIN 4 CONFIDENTIAL ...

Page 60: ...CP RX78 C15 20EE 1 2 3 4 5 6 1 2 3 4 5 6 A B C D E F G PWB assembly MAIN 9 CONFIDENTIAL ...

Page 61: ...CP RX78 C15 20EE 1 2 3 4 5 6 1 2 3 4 5 6 A B C D E F G PWB assembly MAIN 10 CONFIDENTIAL ...

Page 62: ...CP RX78 C15 20EE 1 2 3 4 5 6 1 2 3 4 5 6 A B C D E F G PWB assembly MAIN 11 CONFIDENTIAL ...

Page 63: ...CP RX78 C15 20EE 1 2 3 4 5 6 1 2 3 4 5 6 A B C D E F G PWB assembly MAIN 12 CONFIDENTIAL ...

Page 64: ...CP RX78 C15 20EE 1 2 3 4 5 6 1 2 3 4 5 6 A B C D E F G PWB assembly MAIN 13 CONFIDENTIAL ...

Page 66: ...QR78621 CP RX78 YK No 0628E ...