6

© 2022 S. Himmelstein and Company—all rights reserved. www.himmelstein.com

B. Electrical Installation

B.1 Applicability

This section applies to all MCRT

®

48200V Torquemeters.

B.2 Stator Connectors

Three stator connectors are used, as follows:

• Input Power (2 Pins)

• Analog Output/Cal Enable/Zero (4 Pins)

• Com Port (3 Pins)

If an optional speed pickup is furnished, it will have an

integral 2 pin (Code A) or 3 pin (Code Z) connector.

The

Code Z Zero Velocity Pickup is recommended for use

at low operating speed and for electrically noisy envi-

ronments.

Mating connectors are supplied except if a

complete cable is furnished for the Com Port.

Before wiring mating connectors, refer to Figure 5 for the

connector pin number identification(s). That Figure shows

the stator connector looking down at the torquemeter.

Mating connector pin sequence is their mirror image.

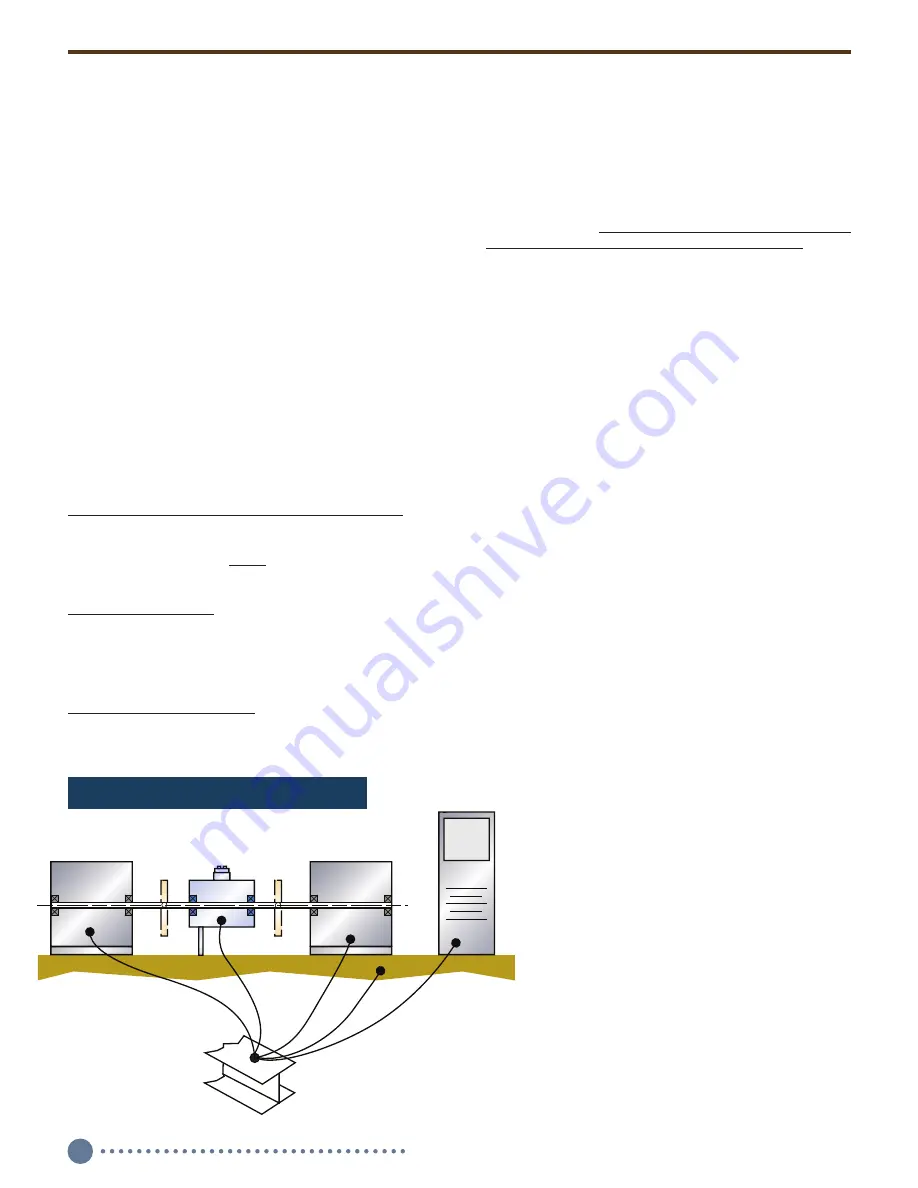

B.2.1 Earth Ground Connection

Connect the Torquemeter stator directly to earth ground, a

buildings’ structural steel or a floor rod. If neither is avail-

able, drive a six foot copper rod into the floor. Then run

separate ground straps between it, the drive motor frame,

the machine base, the torquemeter housing, the load

device and the data acquisition/computer system ground.

Don’t “daisy chain” the connections. See Figures 3 and 4.

If an IGBT-based variable frequency drive (VFD) is used,

follow its installation manual. Improperly installed VFD’s

can cause premature motor and cable failures, and

reading errors from excessive noise. VFD’s should have

shielded power and motor cables. Belden Types 29500

thru 29507 cable are designed for VFD use. See “Cable

Alternatives for PWM AC Drive Applications” available at

www.belden.com. Himmelstein recommends the connec-

tion in

Figure 20

. For best results, use a differential input

amplifier in these electrically noisy environments.

B.2.2 Power Input; 2 Pin Connector

The power connector has two pins with pinout as follows:

Pin 1

Power Return

Pin 2

+ Power In ( 10 to 15 VDC)

Spare mating connectors can be ordered from the factory;

P/N: 320-1285.

Reverse polarity protection is standard. Although any wire

may be used for connections,

shielded cable will perform

best in noisy environments and is recommended

. Note:

the shield should float at the Torquemeter end. The other

end should be tied to earth ground; see Figure 5.

Caution: Don’t connect a Torquemeter to a

Power Supply that also drives inductors or

solenoids. Induced switching transients may

cause damage or noise.

B.2.3 Analog Outputs, Cal Enable, Torque

Zeroing; 4 Pin Connector

Shielded cable is recommended for these connections.

The shield should float at the Torquemeter end and tied

to earth ground at the other end; See Figure 5. Spare

mating connectors can be ordered from the factory; P/N:

320-1287.

B.2.3.1 Analog Outputs

An analog of Torque is output on the four pin connector.

Pin connections are as follows:

Pin 1

Analog Output

Pin 2

Analog Ground

The analog signal may have full scale values as

follows:

Torque CW = +10V, CCW = -10V, or

CW = +5V, CCW = -5V

The default value is 10 Volts. The user may reas-

sign the output voltage selection with the use of

a PC and supplied software. CW torque causes

the shaft to turn CW when viewed from the

driven end. CCW torque causes the opposite

rotation.

B.2.3.2 Cal Check Enable

Internal Calibration Check Circuitry may be

remotely enabled by pin strapping and/or via

Load Device

DAS/Controller

Machine Base

Drive Motor

Torquemeter

Earth Ground

NOTE: Use separate

ground straps.

Figure 3. Correct System Earth Grounding.