Strain Gage Reaction Torquemeters Installation Guide

S. Himmelstein and Company

© 2017 S. Himmelstein and Company—all rights reserved www.himmelstein.com

9

D.2 Allowable Torque Loads

D.2.1 Overload Considerations

Himmelstein Reaction Senors have torque overload ratings between

two (2) and five (5) times their full scale rating, model dependent.

The overload rating of your sensor is listed on the cover sheet. The

torque sensor will not yield (evidenced by a non-return to zero) if

subjected to an instantaneous peak torque up to its overload value.

Full scale and overload ratings are based on the peak stress seen

by the transducer. They are independent of stress duration except,

for cyclical (or fatigue) loading. Virtually all rotary power produc-

ing and absorbing devices produce pulsating rather than smooth

torque. Thus, in addition to its average torque value, the driveline

torque usually includes a fundamental (driving) frequency and

superimposed harmonics. Those torque perturbations can be mul-

tiplied when driveline resonance occurs. Additionally, in produc-

tion and other real-world applications, accidental loads and other

unforseen events can produce higher than expected torque levels.

Please refer to Application Note 221101D for more information.

For these reasons, reserve the region between the peak instan-

taneous torque and the sensor overload rating as a safety margin

for unexpected loads. Do not knowingly operate in the overload

region. When torques are expected to reach or exceed the full scale

rating, change to a higher capacity sensor or one with a higher

overload rating.

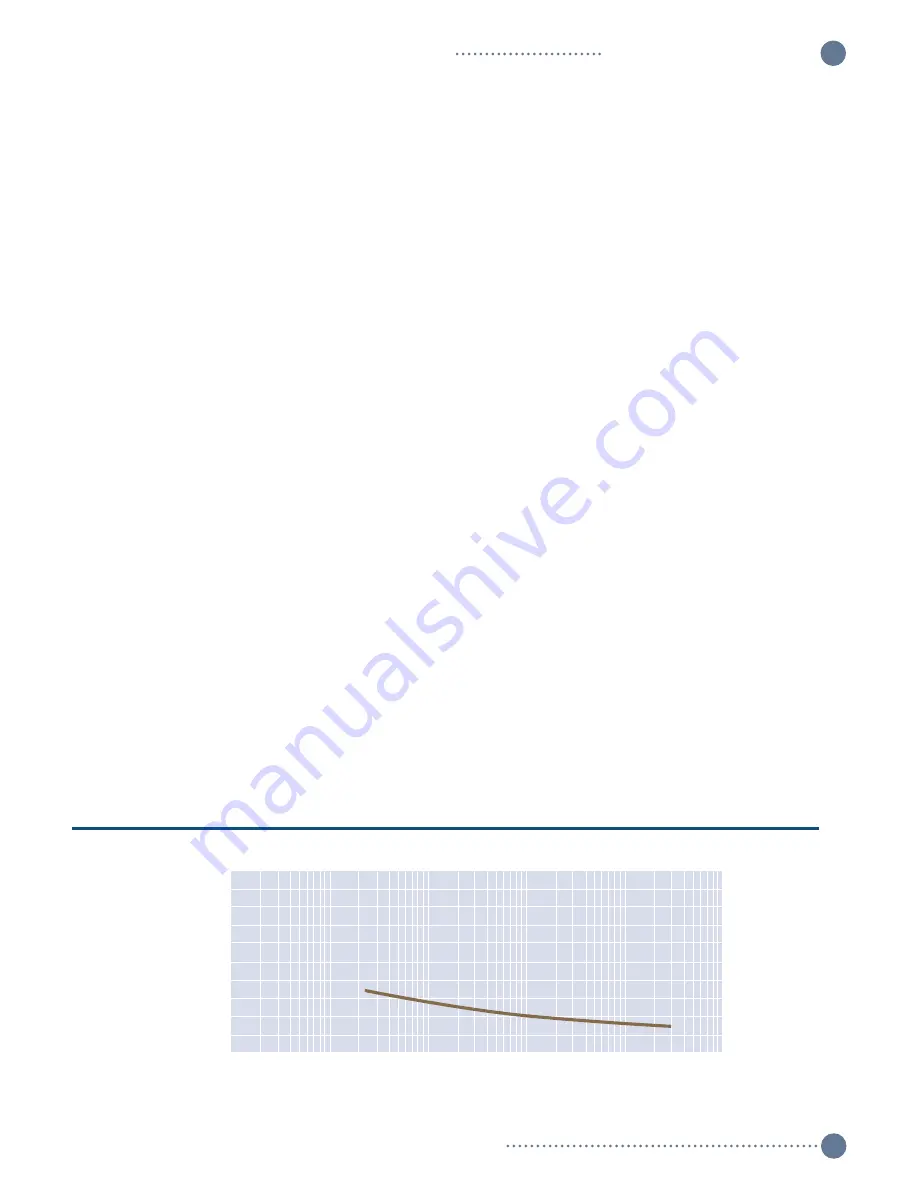

D.2.2 Fatigue Considerations

The sensor has infinite fatigue life with full torque reversals equal to

or less than half the overload rating. If instantaneous peak torques

exceed 50% of the overload rating, fatigue failure can occur.

When operating with peak torques greater than half the over-

load rating, fatigue life is a function of several factors. They include

the torque magnitude, the magnitude and type of extraneous loads

simultaneously applied, the total number of loading cycles, the

driveline damping, etc.

D.3 Allowable Extraneous Loads

Any force or moment the sensor sees, other than the reaction

torque input, is an extraneous load. Depending on the installa-

tion, they can include bending moments and axial thrust; see

Figures 7 and 8

. Rated Torque can be simultaneously applied

with rated bending or thrust loads without damage, provided

the extraneous loads are applied singly. Typical extraneous

load crosstalk is 1 to 2%. Crosstalk signals can be electrically

canceled. Refer to Section A.3.

D.3.1 Bending Loads

Allowable bending loads are model dependent. Most range from

half rated torque to eight times rated torque. Please refer to Model

Specifications for complete ratings.

D.3.2 Thrust Loads

Allowable thrust loads are model dependent. Most range, in

lbf, from rated torque, in lbf-in, to twenty times rated torque.

Please refer to Model Specifications for complete ratings.

D.4 Contaminants

These devices should not be exposed to corrosive or electrically

conductive fluids. They are not waterproof although they are water

resistant. Pure water and hydrocarbon lubricants have no effect

on operation. As a precaution, they should be shielded from direct

liquid spraying.

D.5 Hazardous Environments

If used in a hazardous environment, the sensors must be connected

via approved safety barriers. Safety barriers are sealed, passive

networks installed in each wire that connects the hazardous and

safe locations. They limit electrical energy passing between the two

locations to a safe value.

10

3

10

4

10

5

10

6

10

7

10

8

Fatigue Life, Cycles

200

180

160

140

120

100

80

60

40

20

0

Minimun Stress, KSI

Figure 11. Typical Fatique Life Characteristics