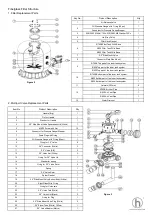

Fiberglass Filter Structure

Key No.

Product Description

Qty

1

Air Release Valve

1

Oil Pressure Gauge with O-ring (40 psi)

1

Connector for Pressure Gauge/Stopper

1

3

03013003 M8 Nut*12Pc; 03012003 M8 Washer*12Pc

1

4

Lid (Grey Color)

1

5

Filter Neck Gasket

1

700B F e Ta W h Ba e

1

800 F e Ta W h Ba e

1

900 F e Ta W h Ba e

1

7

2.0" Side Mount Valve

1

8

Connector Plate Side Mount

1

700B T a f he

e a

e

1

800 T a f he

e a

e

1

900T a f he

e a

e

1

700B B

a f he

e a

e

1

800 B

a f he

e a

e

1

900 B

a f he

e a

e

1

11

Laterals (233mm)

8

700B A Ve P e

1

800 A Ve P e

1

900 A Ve P e

1

13

Water Drain set

1

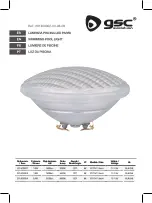

Item No.

Product Description

Qty

1

Handle (Big)

1

2

Pin for Handle

1

3

Washer for Handle

1

4

2.0" Side Mount Valve Squareness Lid (White)

1

5

M6*32 Screw with Nut

10

6

Connector for Pressure Gauge/Stopper

1

7

Drain Plug with O-ring

1

8

Oil Pressure Gauge with O-ring (40psi)

1

9

O-ring for 2.0" Union

8

10

2.0" Connector (White)

3

11

2.0" Union (A/E)

3

12

2.0" Union Nut (White)

3

13

O-ring for 2.0" Valve Lid

1

14

Washer for spring

1

15

O-ring for 2.0" Valve Rotor

2

16

Spring

1

17

2.0" Valve Rotor

1

18

Spider Gasket

1

19

2.0" Side Mount Valve Bottom Body(White)

1

20

Sight Glass With O-ring

1

21

O-ring for Union tale

1

22

2.0" Union Tale (White)

1

23

2.0" Union Nut (Black)

2

24

O-ring for Plug

1

25

2.0" Side Mount Valve Plug (White)

2

26

2.0" Elbow Tube (White) 183mm

1

27

2.0" Union Adaptor (Metric)

1

12

2. Multiport Valve Replacement Parts

1. Filter Replacement Parts

2

6

9

10

Figure 2

Figure 3