www.alcamobil.de

Ignoring the following instructions can lead

both to injury and damage to property.

When using the compressor never leave it

unattended.

1. Use a 230V power source.

2. The compressor is not designed for

continuous operation.

3. Operation over a longer period may lead

to overheating and destruction.

A slow operation or when the metal is hot,

is a sign that the compressor is running

too long. Turn off the device immediately

and allow it to cool for at least 10 minutes.

4. Do not let the compressor at 5 bar run

longer than 7 minutes.

Tyre inflation

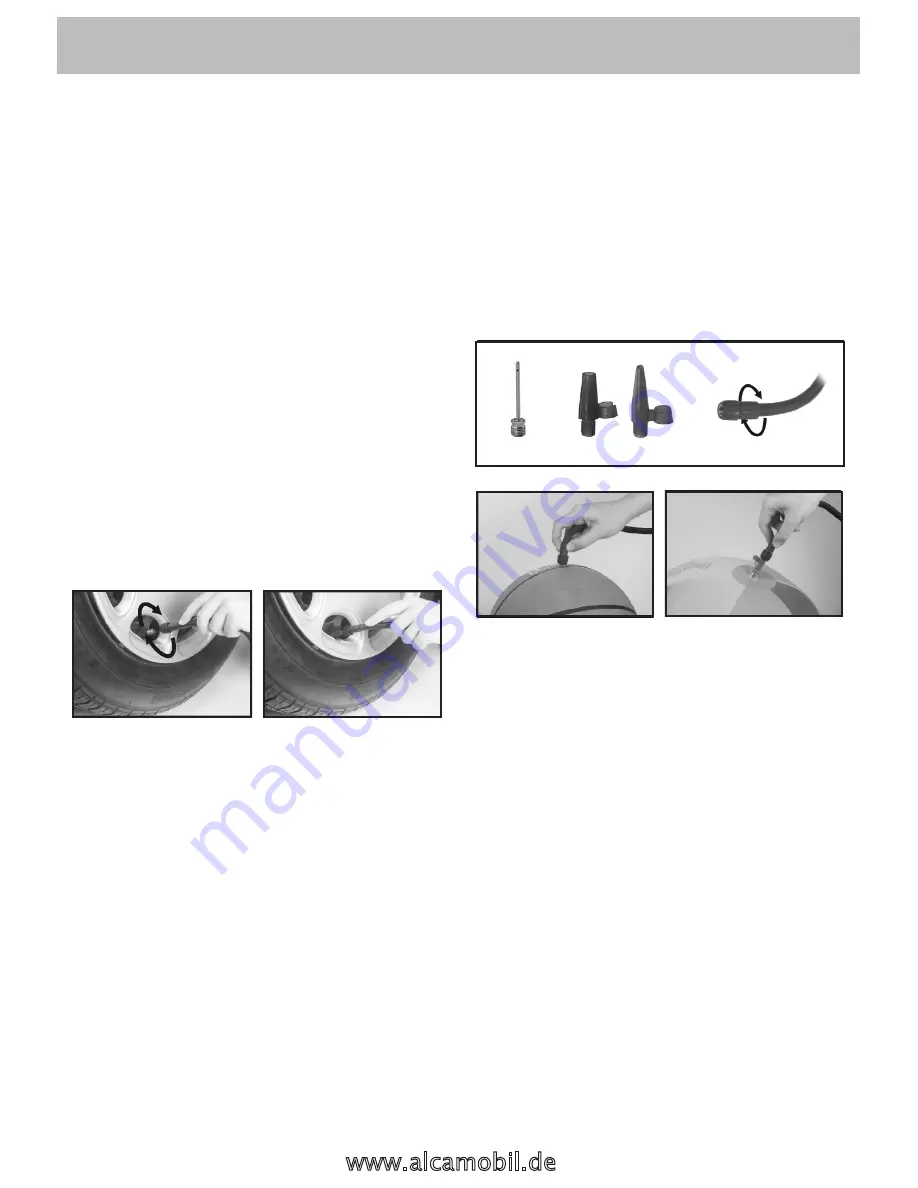

1. Screw the valve connecting of the hose

on the valve.

Caution: Make sure that the valve

connection is firmly seated on the valve.

2. Insert the plug into the socket.

3. Turn the compressor on (switch in

position „I“)

4. When the desired pressure is reached,

turn the compressor off (switch in position

„0“). Unscrew the valve connection again

from the valve. Disconnect the plug from

the socket.

The inflation of inflatable play equipment

1. Select the appropriate adapter and screw

it on the valve connection (Pic. 3).

2. Check the appropriate pressure based on

the list below. The list is a guide only.

For accurate pressure determination use

the instructions of the manufacturer of

inflatable play equipment.

3. Insert the adapter into the play equipment

(Pic. 4).

4. Insert the plug into the socket (230V) and

turn the compressor on (switch in

position „I“).

5. When the desired pressure is reached,

remove the plug from the socket.

6. Remove the adapter from the inflatable

device and the adapter of the valve

connection.

Recommended pressure

Do not inflate too much. Never exceed the

recommended pressure. The device may

burst and cause injury.

Trouble shooting:

The compressor does not start / does not

inflate

1. Push the plug into the socket properly

and check the connection.

2. Check the plug and the socket for

contamination and function.

Be sure to use non-conductive objects,

so no metal or similar.

3. Fuse in the compressor.

The compressor operates without infla-

ting

1. Make sure that the connector is sitting

tight on the valve.

2. Check the article for leaks.

3. Check the hose and connection

English

Pic. 2

Pic.1

Pic. 3

Pic. 4