Page 6

For technical questions, please call 1-888-866-5797.

Item 57719

SPECIFICATIONS

Battery

57367 Hercules 12V Li-ion

(sold separately)

Charger

56561 Hercules 12V Li-ion

(sold separately)

No Load Speed

±

SPM

Stroke Length

5/8"

SETUP–BEFORE USE

Read the ENTIRE IMPORTANT

SAFETY INFORMATION section at the

beginning of this manual including

all text under subheadings therein

before set up or use of this product.

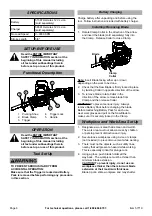

Functional Description

4

3

1

1. Pivoting Shoe

2. Blade Clamp

3. Trigger

4. Trigger Lock

5. Handle

2

5

OPERATION

Read the ENTIRE IMPORTANT

SAFETY INFORMATION section at the

beginning of this manual including

all text under subheadings therein

before set up or use of this product.

Tool Set Up

TO PREVENT SERIOUS INJURY FROM

ACCIDENTAL OPERATION:

Make sure that the Trigger is locked and Battery

Pack is removed before performing any procedure

in this section.

Battery Charging

Charge battery after unpacking and before using the

tool. Follow instructions included with battery charger.

Installing / Removing Blade

1. Rotate Clamp Collar in the direction of the arrow

and insert the blade (sold separately) fully into

the Clamp. Release Collar to close Clamp.

Blade

Clamp

Collar

Note:

Insert Blade facing either up or down

depending on the work to be done.

2. Check that the Saw Blade is firmly locked in place

by twisting Collar in opposite direction of the arrow.

3. To remove blade, rotate Collar in the

direction of the arrow, remove blade from

Clamp and then release Collar.

WARNING!

To prevent serious injury: Always

remove Battery Pack before changing the blade.

Before reattaching Battery Pack for each use,

wear work gloves and pull on the Saw Blade to

make sure it is securely locked in the Clamp.

Workpiece and Work Area Set Up

1. Designate a work area that is clean and well lit.

The work area must not allow access by children

or pets to prevent distraction and injury.

2. Secure loose workpieces using a vise or clamps

(not included) to prevent movement while working.

3. There must not be objects, such as utility lines,

nearby that will present a hazard while working.

This is especially critical for plunge cuts.

4. Using a glove, push blade holder all the

way back. The workpiece must be thinner than

minimum blade extension.

CAUTION! To prevent injury, do not use on

workpieces thicker than the minimum blade

extension at their maximum thickness.

Blade tip can strike workpiece and may shatter.