30

REDUCED SUCTION

Clogged filters

Check the status of the filters; in case

replace the filters with a new set.

Air leaks on the machine

Check that there are no drafts of

air or strange openings on the

carpentry. If possible try to seal

everything with silicone.

Unbalanced impeller

Check the condition of the impeller,

checking that it has no broken parts

or dirt on the blades. Remove the

fan assembly and clean the impeller

completely.

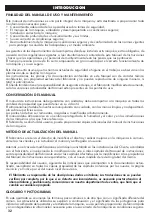

TABLE OF SCHEDULED MAINTENANCE

PERIODIC CHECKS

TYPE OF CHECK OR

MAINTENANCE

METHOD

FREQUENCY

1

GENERAL CHECK OF THE CONDITION OF THE AIR CLEANER

VISUAL

DAILY

2

CLEANING

MANUAL

See note A

3

CHECK OF THE CONDITION OF THE SEALS

VISUAL

150 HOURS

4

CHECK OF TIGHTNESS OF NUTS AND BOLTS

MANUAL

150 HOURS

5

CHECK OF FILTER CLOGGING

VISUAL OR MANUAL

600 HOURS See note B

6

CHECK OF EXTRACTOR FAN

MANUAL

See note C

7

REPLACEMENT OF BEARINGS

MANUAL

40000 HOURS See note D

NOTE A

The cleaning intervals vary according to the type of fluid conveyed and its concentration and also according

to the type of work environment in which it is used. The end user must therefore define a cleaning interval

suitable to always keep the machine perfectly clean; the accumulation of material on the fixed parts must

not be more than 5 mm thick.

NOTE B

A special device (optional) on the equipment signals the need to replace the filters. It is however recom-

mended to check whether the filters are clogged for maximum suction and machine efficiency; for this

reason the cleaning interval described in the filter paragraph should be respected and the entire filter set

should be replaced at least once a year. The filters deteriorate even if they are not used very often.

NOTE C

The fan extractor must be monitored at intervals established by the user to check that it is good working

order, to check for faults or damage to the impeller and to check that the electric motor is in good condition.

NOTE D

This is the lifecycle defined for the bearings, however due to external factors such as increased vibrations for

a certain period of time the replacement of the bearings may have to be carried out at shorter intervals. At

the end of their lifecycle, the bearings should be replaced even if apparently they seem in good condition.

OPERATOR’S NOTES

DETAILS OF MAINTENANCE OPERATIONS

The following table must be completed by a specialized technician authorized by HELVI S.p.A..

It is of fundamental importance to keep these notes up-to-date in order to have an affective record of the

problems encountered and the maintenance performed; in this way future malfunctions could be settled

in a short time and with the least economic expenditure.