UK

5.0

Cleaning and maintenance

All work may only be carried out by a qualified person. All relevant safety regulation, national standards and

norms are to be adhered to!

Make sure before the cleaning that the unit is isolated from the mains and id secured against restarting

with an isolator switch!

–

Impeller must stand still

– Excessive deposit of dirt, dust, grease and other materials on the impeller, motor and between casing and impeller is

to be avoided and has to be prevented by periodical cleaning

– Provided that the device takes over a supply-technically important function, a maintenance has to be carried out in

intervals of max. 6 months, in case of longer standstill at restart.

–

All work may only be carried out by a qualified person.

– The following checks are to be carried out:

• Bolted connections especially impeller fixing.

Do not loosen screws!

• Bearing noise

• Damages

• Vibrations

• Dirt build-up

• Current consumption

• Functioning of safety components

– Keep a maintenance book for the fan and enter the accomplished checks and examination results.Compare the

results with the results from earlier examination. Should the parameters deviate please contact the manufacturer.

5.1

Cleaning

Make sure before the cleaning that the unit is isolated from the mains!

Wet cleaning while energized can lead to an electric shock.

– Regular inspection, if necessary with periodic cleaning, in order to avoid unbalance by contamination.

Clean air flow area of fan

– Do not use aggressive, paint solvents.

– High pressure cleaner or jet water is not permitted!

5.2

Indications – Disturbance origins

– Abnormal noises can mean worn out ball bearings..

– Vibrations can originate from unbalanced or dirty impellers or due to installation.

5.3

Spare parts

Faulty fans are to be exchanged according to guideline 94/9 EEC completely. Own repair attempts are strictly forbid

den! An optimal operational safety of the fans is ensured only with repairs by the manufacturer.

5.4

Putting out of service and dispose

The generally valid regulations for occupational safety and accident prevention regulations have to be

adhered to !

–

All work may only be carried out by a qualified person.

– Use suitable lifting equipment and fixing devices to dismantle the fan.

– Dispose the fan components according to the valid regulations and laws.

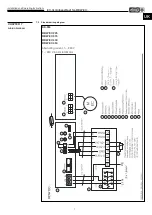

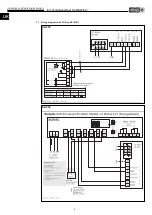

6.0

Indications - Disturbance origins

Releasing the integrated electronic temperature protection can be caused through:

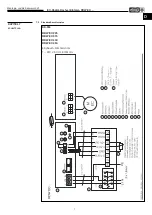

– Disturbances by electrical influence at the input lines can lead to the shutdown of electronics. This is to be recogni-

sed by a “blinking” of the red error LED and can be repaired, if necessary, by operating the reset push button or by

switching on and off.

– Fault in the electronics

–

build- up of dirt, hard running impeller and/or ball bearing failure

–

too high air flow temperature

Abnormal noises can mean

–

worn out ball bearings

–

bad vibration isolation to other buildings and ducting systems

Vibration can originate from:

–

unbalanced or dirty impellers

–

bad vibration isolation to other buildings and ducting systems

Extreme reductions in performance can occur

,

–

if resistance to air stream through ducting and accessories (grilles, shutters, filters etc.) is higher than designed

6

EC-Centrifugal-Roof fan RDW EC ..

Installation and Operating Instructions

WARNING

CHAPTER 5

CLEANING AND

MAINTENANCE

CHAPTER 6

DISURBANCE ORIGINS

NOTE

☞

WARNING

WARNING

ATTENTION