Helios PD2-6100 Strain Gauge, Load Cell, and mV Meter

Instruction Manual

47

Programmable Function Keys

User Menu (

user

)

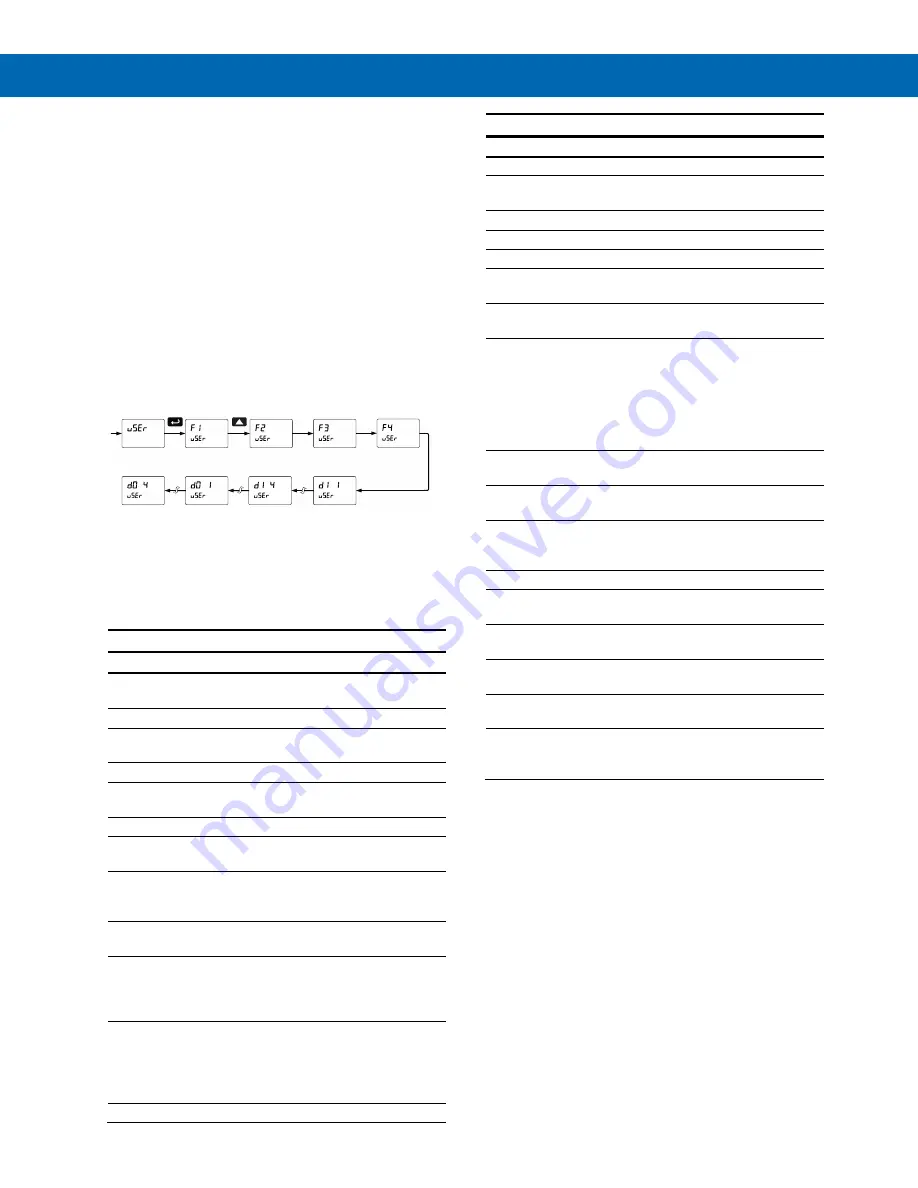

The

User

menu allows the user to assign the front

programming buttons function keys F1, F2, and F3,

the digital input F4 (located on the input signal

connector), and four digital inputs (located on the

digital I/O connector) to access most of the menus or

to activate certain functions immediately (e.g. reset

max & min, hold relay states, etc.). This allows the

meter to be greatly customized for use in specialized

applications.

The four digital outputs can be assigned to a number

of actions and functions executed by the meter (i.e.

alarms, relay acknowledgement, reset max, min, or

max & min, tare, and reset tare). The digital outputs

can be used to trigger external alarms or lights to

indicate these specific events.

Function Keys & Digital I/O

Available Settings

Refer to the following table for descriptions of each

available function key or digital I/O setting.

Function Keys & Digital I/O Available Settings

Display

Description

Rst Hi

Reset the stored maximum display

value

Rst Lo

Reset the stored minimum display value

Rst HL

Reset the stored maximum & minimum

display values

tare

Capture tare and zero the display

Rst tr

Reset captured tare and resume normal

operation

relay

Directly access the relay menu

Set 1

*

*

Directly access the set point menu for

relay 1 (*through 4)

Rly d

Disable all relays until a button

assigned to

enable relays

(

Rly E

) is

pressed

Rly E

Enable all relays to function as they

have been programmed

O Hold

Hold current relay states and analog

output as they are until a button

assigned to

enable relays

(

Rly E

) is

pressed

d Hold

Hold the current display value, relay

states, and analog output momentarily

while the function key or digital input is

active. The process value will continue

to be calculated in the background.

Ln1 Hi

Display minimum display value on line 1

Function Keys & Digital I/O Available Settings

Display

Description

Ln1 Lo

Display minimum display value on line 1

Ln1 HL

Display maximum & minimum display

values on line 1

Ln2nmV

Display the mV input on line 2

Ln2 Hi

Display maximum display value on line 2

Ln2 Lo

Display minimum display value on line 2

Ln2 HL

Display maximum & minimum display

values on line 2

zero

Zero the display (this is different from

capture tare

because it cannot be reset)

F On 1

*

*

Force relay 1 (*through 4) into the on

state. This function is used in

conjunction with a digital input to

achieve interlock functionality. See

Setting Up the Interlock Relay (Force

On) Feature

about interlock relays.

Contrl

Directly access the

Manual Control

menu

disabl

Disable the selected function key or

digital I/O

AcH

Acknowledge all active relays that are in

a manual operation mode such as auto-

manual or latching

Reset

Directly access the reset menu

nmenu

Mimic the menu button functionality

(digital inputs only)

rigHt

Mimic the right arrow/F1 button

functionality (digital inputs only)

up

Mimic the up arrow/F2 button

functionality (digital inputs only)

Enter

Mimic the enter/F3 button functionality

(digital inputs only)

Alnm 1

*

*

Provide indication when alarm 1

(*through 4) has been triggered (digital

outputs only)