Information for OEM and Setup users | Commissioning

II

4.6.3

Configuring axes for encoders with EnDat interface

If the corresponding encoder input has already been assigned to an axis, a

connected encoder with EnDat interface is automatically detected upon restart, and

the settings are adapted. Alternatively, you can assign the encoder input after you

have connected the encoder.

Prerequisite:

An encoder with EnDat interface is connected to the product.

Settings

►

Axes

►

<Axis name>

►

Encoder

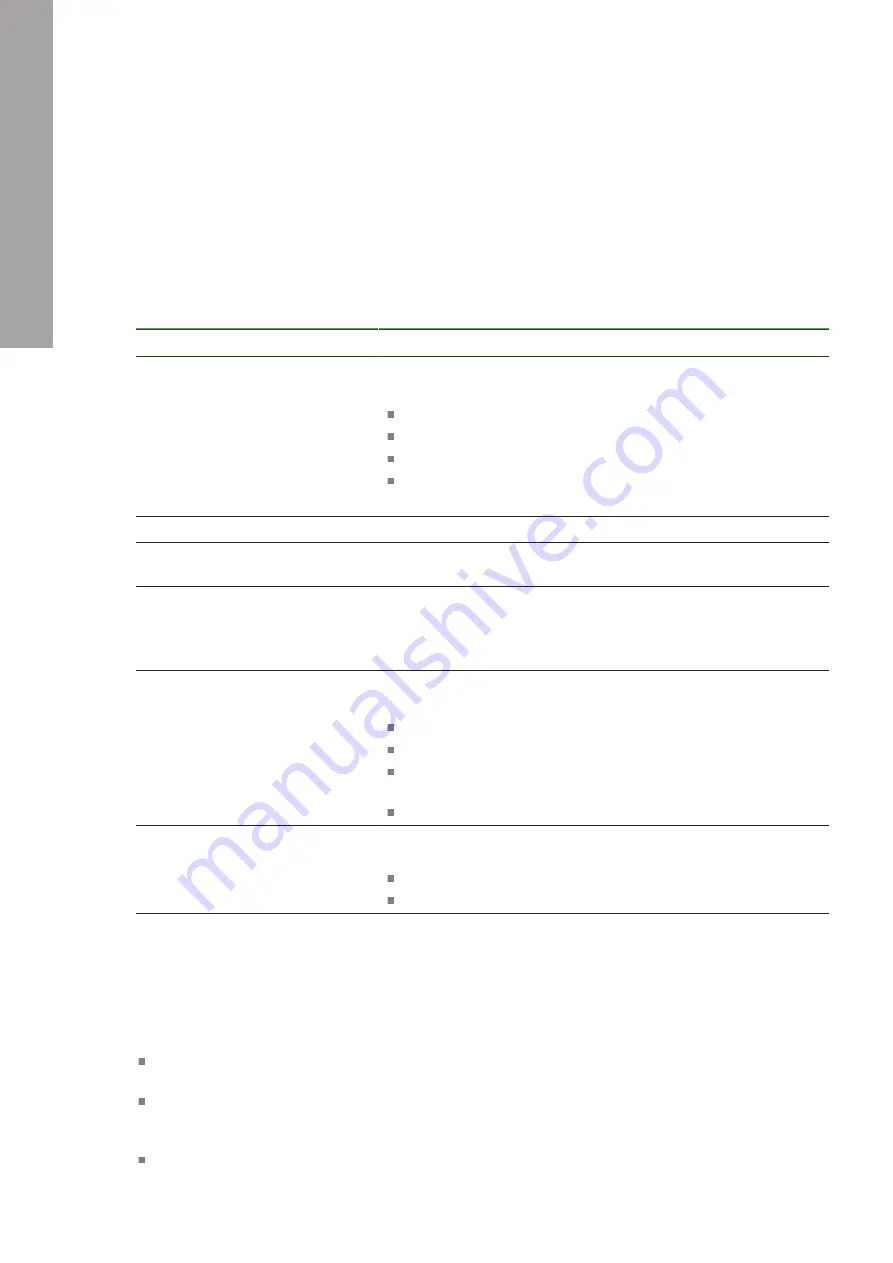

Parameter

Explanation

Encoder input

Assignment of the encoder input to the axis of the product

Settings:

Not connected

X1

X2

X3

Interface

Automatically detected

EnDat

interface type

ID label

Information on the encoder that was read from the electronic ID

label

Diagnosis

Results of encoder diagnostics, evaluation of encoder function

(e.g., based on functional reserves)

"Diagnostics for encoders with EnDat inter-

Encoder model

Connected encoder model

Settings:

Linear encoder

: Linear axis

Angle encoder

: Rotary axis

Angle encoder as linear encoder

: Rotary axis is displayed as

linear axis

Default value: Depending on the connected encoder

Mechanical ratio

For display of a rotary axis as a linear axis:

traverse path in mm per revolution

Setting range:

0.1 mm ... 1000 mm

Default value:

1.0

Reference point displacement

Configuration of the offset between the reference mark and the

zero point

"Reference point displacement", Page 87

Using an

Angle encoder as linear encoder

Certain parameters must be taken into account when configuring an angle encoder

or rotary encoder as a linear encoder, in order to prevent an overrun of the system.

The mechanical ratio must be chosen such that the maximum traverse range of

21474.483 mm is not exceeded

The reference mark shift should only be used when considering the maximum

traverse range of

±

21474.483 mm, since this limit applies both with and without

a reference mark shift

Only for multiturn rotary encoders with EnDat 2.2:

the rotary encoder must be

mounted such that an overrun of the rotary encoder does not affect the machine

coordinates negatively

86

HEIDENHAIN | GAGE-CHEK 2000 | Operating Instructions | 06/2022

Summary of Contents for GAGE-CHEK 2000

Page 1: ...GAGE CHEK 2000 Operating Instructions Evaluation Unit English en 06 2022...

Page 3: ...I General information...

Page 7: ...1 Fundamentals...

Page 14: ...2 Safety...

Page 19: ...3 Basic operation...

Page 43: ...II Information for OEM and Setup users...

Page 48: ...1 Transport and storage...

Page 54: ...2 Mounting...

Page 60: ...3 Installation...

Page 72: ...4 Commissioning...

Page 121: ...5 Setup...

Page 150: ...6 File management...

Page 157: ...7 Settings...

Page 172: ...8 Servicing and maintenance...

Page 184: ...9 Removal and disposal...

Page 186: ...10 Specifications...

Page 194: ......

Page 195: ...III Information for the Operator user...

Page 240: ...14 What to do if...