MEGAFL

O HE

21

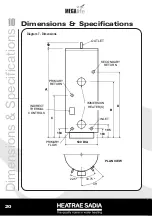

Table 2 - Dimensions

Table 3 - Direct units - Technical specifications

Table 4 - Indirect units - Technical specifications

NOTE

Coil heating performance based on a primary flow rate of 15 l/min at 80

o

C.

Temperature rise is from 15

o

C to 60

o

C.

SIZE

DIRECT INDIRECT

A

B

C

D

100

D 758

n/a

n/a

505

100

CL

758

n/a

560

505

120

D

880

n/a

n/a

615

120

CL

880

n/a

560

615

150

D

1064

n/a

n/a

779

150

CL

1064

n/a

610

779

170

D

1190

760

n/a

880

170

CL

1190

n/a

710

880

210

D

1448

849

n/a

1081

210

CL

1448

n/a

760

1081

TYPE

DIMENSIONS (mm)

SIZE

EMPTY

FULL

LOWER (3kW)

UPPER +

LOWER (6kW)

UPPER

BOOST (3kW)

100

24

124

89

n/a

n/a

120

26

146

107

n/a

n/a

150

29

179

134

n/a

n/a

170

31

201

152

76

64

210

42

252

187

94

88

UNIT WEIGHT (kg)

HEAT UP TIMES (mins)

SIZE

EMPTY

FULL

SURFACE

(sq.m)

HEAT UP

(mins)

RECOVERY

(mins)

RATING

(kW)

100

25

125

0.521

23

18

11.8

120

27

147

0.521

27

22

11.8

150

31

181

0.586

32

26

12.5

170

34

204

0.716

31

26

14.5

210

45

255

0.782

33

27

16.9

COIL SPECIFICATIONS

UNIT WEIGHT (kg)