Heat Controller, Inc.

MGD-B SERIES GAS FURNACE

Installation Instructions

Mortex Products Inc. / Fort Worth, TX 76106

G18D Installation Instructions

4

RETURN AIR

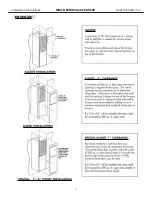

ALCOVE INSTRUCTION

The furnace may be installed free standing or in an

alcove with a free flow of air back to the furnace. A

minimum of 18” shall be provided at the front for return

air and service access.

CLOSET INSTALLATION – 6 in.

Note: If return air is through a side wall, there must be a

minimum of 6-in. clearance from side wall to furnace in

addition to 6-in. minimum clearance from inside of closet

door to front of furnace.

If a louvered door complying with the minimum air

requirements is used, the front clearance my be reduced

to 1”.

CLOSET INSTALLATIONS

Additional Requirements:

Concerning under floor or ceiling return air systems, the

following item (1 – 10) must be adhered to:

1. The return-air opening into the closet, regardless of

location, is to be sized not less than specified on the

appliance rating plate.

2. If the return-air opening is located in the floor of the

closet (versus the vertical front or side wall), the

opening is to be provided with means to prevent its

inadvertent closure by a flat object placed over the

opening.

3. The cross-sectional area of the return system (when

located in the floor or ceiling of the manufactured

home) leading into the closet is to be not less than

that of the opening specified on the appliances

rating plate.

4. The total free area of openings in the floor or ceiling

registers serving the return-air duct system is to be

not less than 150% of the size opening specified on

the appliance rating plate. At least one such register

is to be located where the likelihood of its being

covered by carpeting, boxes, and other objects is

minimized.

5. Materials located in the return duct system have a

flame spread classification of 200 or less.

6. Non-combustible pans having one-inch upturned

flanges are located beneath openings in the floor

return duct system.

7. Wiring materials located in the return duct system

conform to Article 300-22 (B&C) of the National

Electric Code, ANSI / NFPA-70.

8. Gas piping is not run in or through the return duct

system.

9. The negative pressure in the closet, as determined by

test with the air-circulating fan operating at high

heating speed and the closet door closed, is to be

not more negative than minus 0.05-inch water

column.

10. For floor return systems, the manufactured home

manufacturer or installer shall affix a prominent

warning where it is easily read when the closet door

is open.

G18D Series Gas Furnace

INSTALLATION INSTRUCTIONS

HAZARD OF ASPHYXIATION

DO NOT COVER OR RESTRICT

FLOOR OPENING, or equivalent

!

WARNING

or other objects is

may be reduced

4