Heat & Glo • Supreme-XTS, Grand-XTS • 349-901 Rev. G • 9/08

40

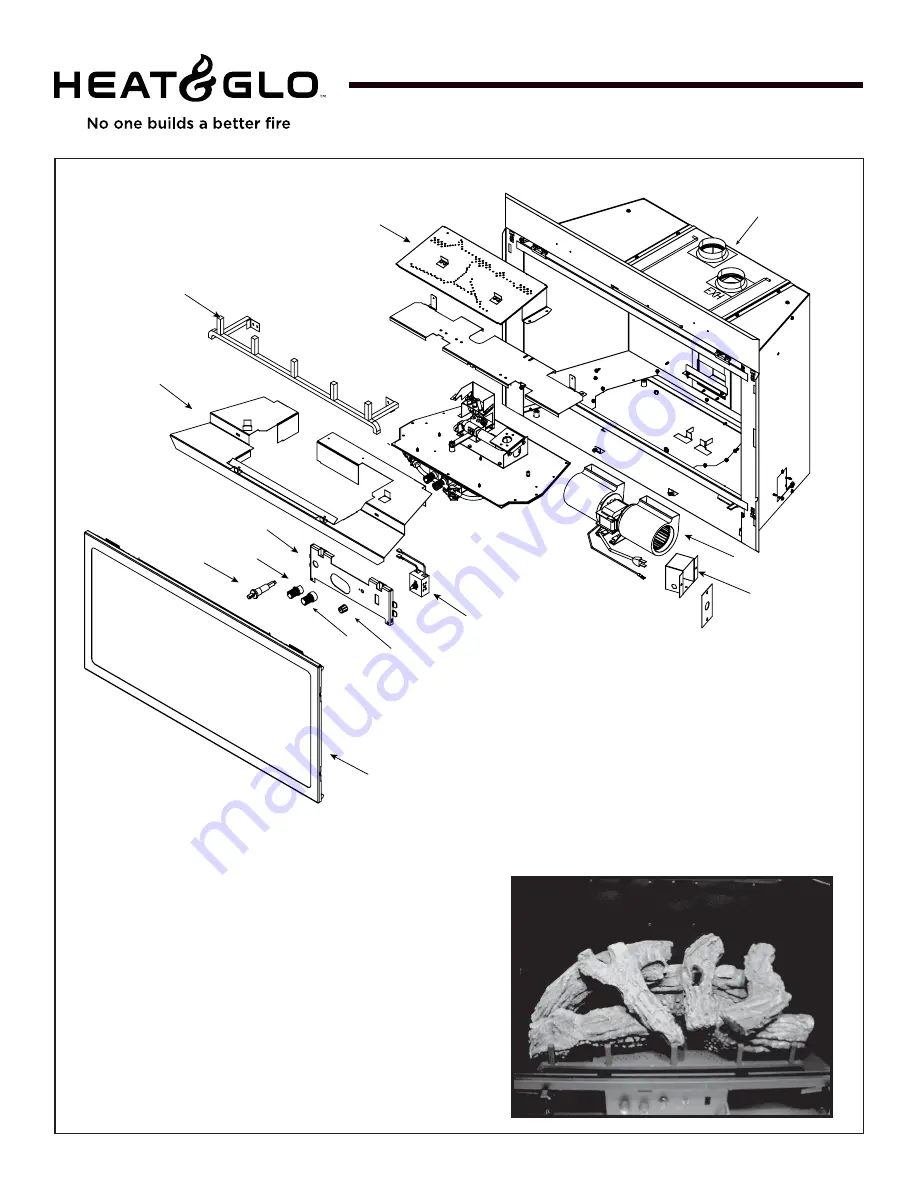

Service Parts Diagram

GRAND-XTS

Beginning Manufacturing Date: Aug. 2007

Ending Manufacturing Date: ______

Service Parts

Part number list on following page.

Log Set Assembly

1

2

3

7

6

4

5

8

20

19

18

17

16

15

14

13

12

11

10

9