6

1. Never unscrew any connecting parts while the tank is pressured.

2. Never disassemble any electrical parts before disconnecting the plug.

3. Never adjust the safety valve carelessly.

4. Never use the compressor when the voltage is too low or too high.

5. Never use an electric wire more than 5m long with less than a 1.5mm²

section rated to 16A.

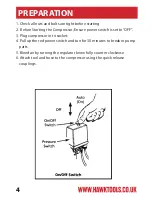

6. Never disconnect the plug to stop the compressor. Set the switch knob

to “off” and follow instructions on page 5.

7. If the release valve doesn’t work when the motor is stopped find the

cause immediately so as not to damage motor.

8. After motor has been switched off and compressed air has been

safely discharged, Switch off and disconnect the plug to cut off the

power supply. Never leave compressor plugged in when not in use.

9. Never operate near flammable gas or vapour.

WARNINGS

Summary of Contents for HWKAC1

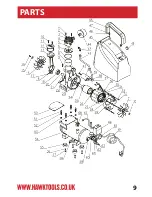

Page 9: ...PARTS 9...