AXIS4000

W

HEEL

A

LIGNMENT

S

YSTEM

HAWEKA Wheel Alignment –AXIS4000

35

Front axle measurement

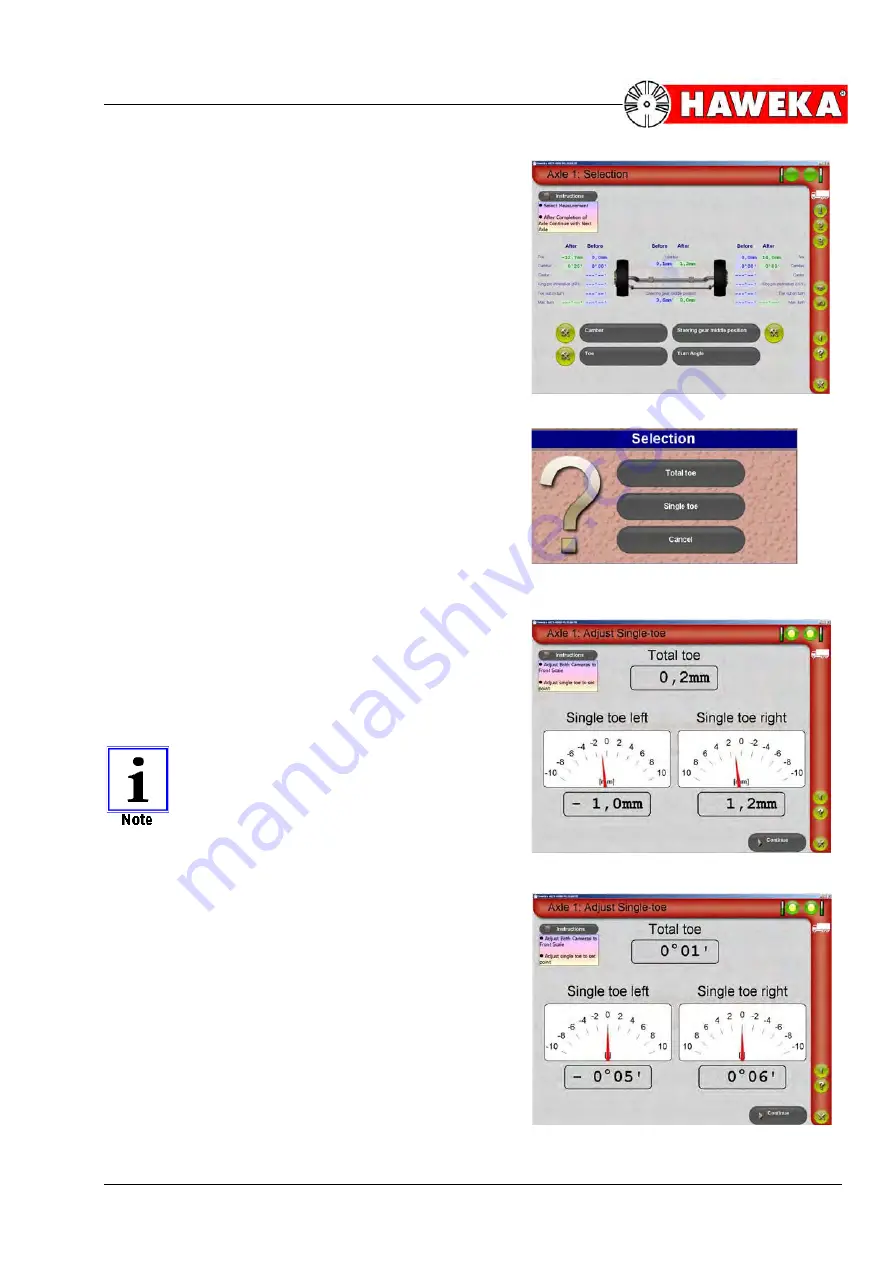

Once the desired NOMINAL value is adjusted, the pro-

cedure is completed with the "

Continue

" button.

•

The program changes back to the overview screen

for the selected axle and not only shows the meas-

ured values (BEFORE column) but also the newly ad-

justed values (AFTER column).

(Fig. 55)

Adjusting the single toe for front axles with inde-

pendent wheel suspension

•

On the selection screen for adjustments, select

Sin-

gle toe

.

(Fig. 56)

•

The single toe values for the left and right sides are

shown on two displays for adjusting the NOMINAL

value. The current values and total toe are displayed

analogue and digital in [mm] for the entire duration

of adjustment.

(Fig. 57)

If the toe value is needed in degrees, then the

display can be changed from [mm] to [de-

grees].

(Fig. 58)

On this topic, please refer to Point 7.2.8 Ex-

tended settings.

(Fig. 58)

(Fig. 57)

(Fig. 56)

(Fig. 55)

Summary of Contents for 924 000 010

Page 2: ......