Page 3 of 7

IND100148-7 - Rev 06 - 16 Feb 2015 - Created by: 363

Hatteland Display AS, Stokkastrandvegen 87B, N-5578 Nedre Vats, Norway

Tel: (+47) 4814 2200 - [email protected] - www.hatteland-display.com

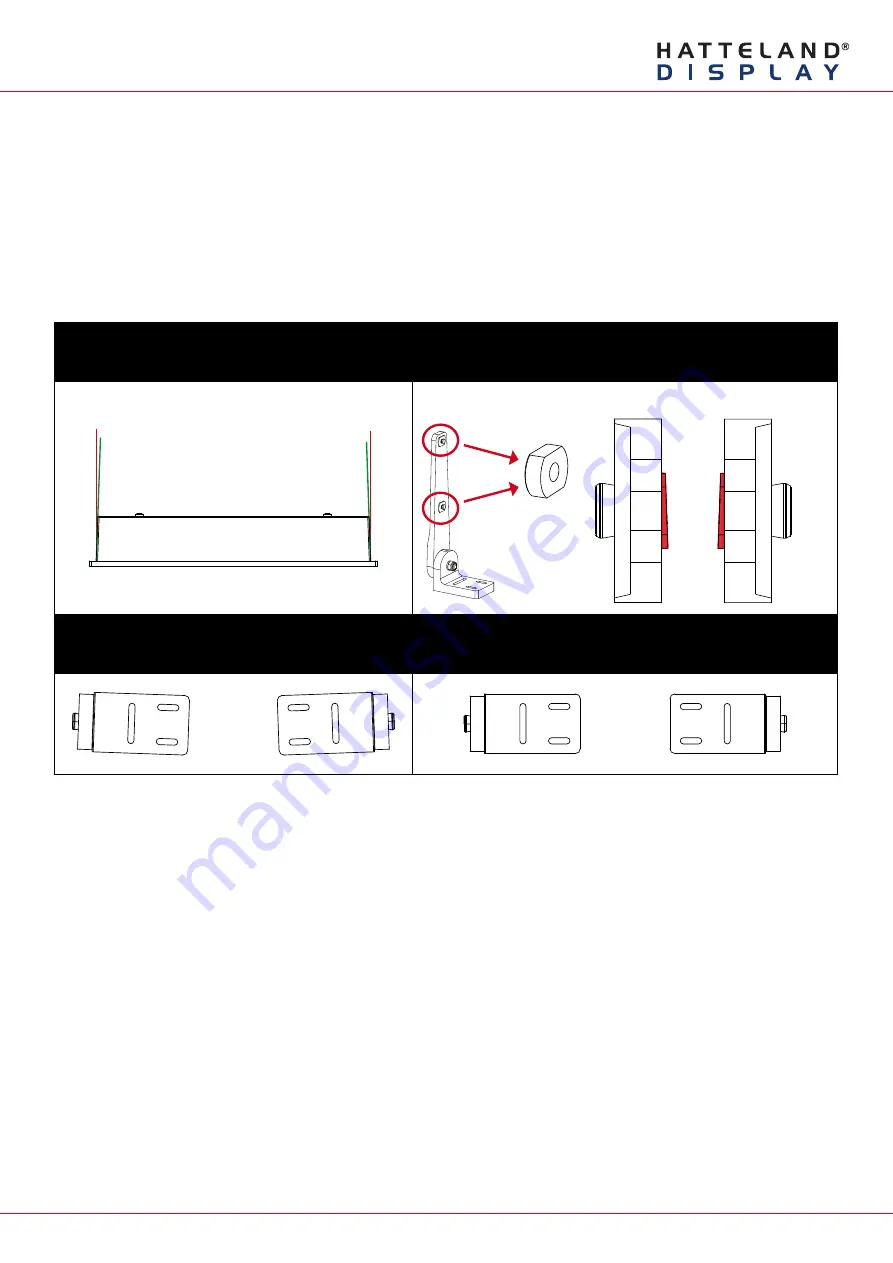

Important to know about LEFT and RIGHT brackets

Throughout the following installation procedure for both BRD and TMB brackets, it is important to understand the

difference between LEFT and RIGHT brackets. The Display and Panel Computer chassis are not 100% square

boxed, but are slightly designed with a minor narrow angled chassis towards the rear (FIG1) to allow easier “drop-

in” of units into consoles. Likewise to get a correct footprint placement of the brackets, both brackets feature a slight

angled design on the oval circled cut shaped block to compensate for this (FIG2) making LEFT and RIGHT bracket

slightly different and naturally has to be correctly mounted.

Please ensure that LEFT and RIGHT brackets are as indicated in FIG4, and not as shown in FIG3 below.

FIG 1

Red Line straight up

Green Line indicates slight angled design of chassis

FIG 2

Location of angled block,

and seen straight from top showing slight angle

LEFT BRACKET

RIGHT BRACKET

FIG 3 - Seen from under bracket base

Wrong mounting of LEFT / RIGHT Brackets

Indicating footprint is incorrect

FIG 4- Seen from under bracket base

Correct mounting of LEFT / RIGHT Brackets

Indicating footprint is correct