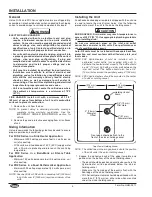

2. Center punch and drill a 3/4" (19 mm) pilot hole at each of

the two center marks on the template.

NOTE: The pilot holes are for cutting larger holes with a

knockout hole punch.

3. Remove the template and cut a 2" (51 mm) diameter hole

at each pilot hole location using a knockout hole punch.

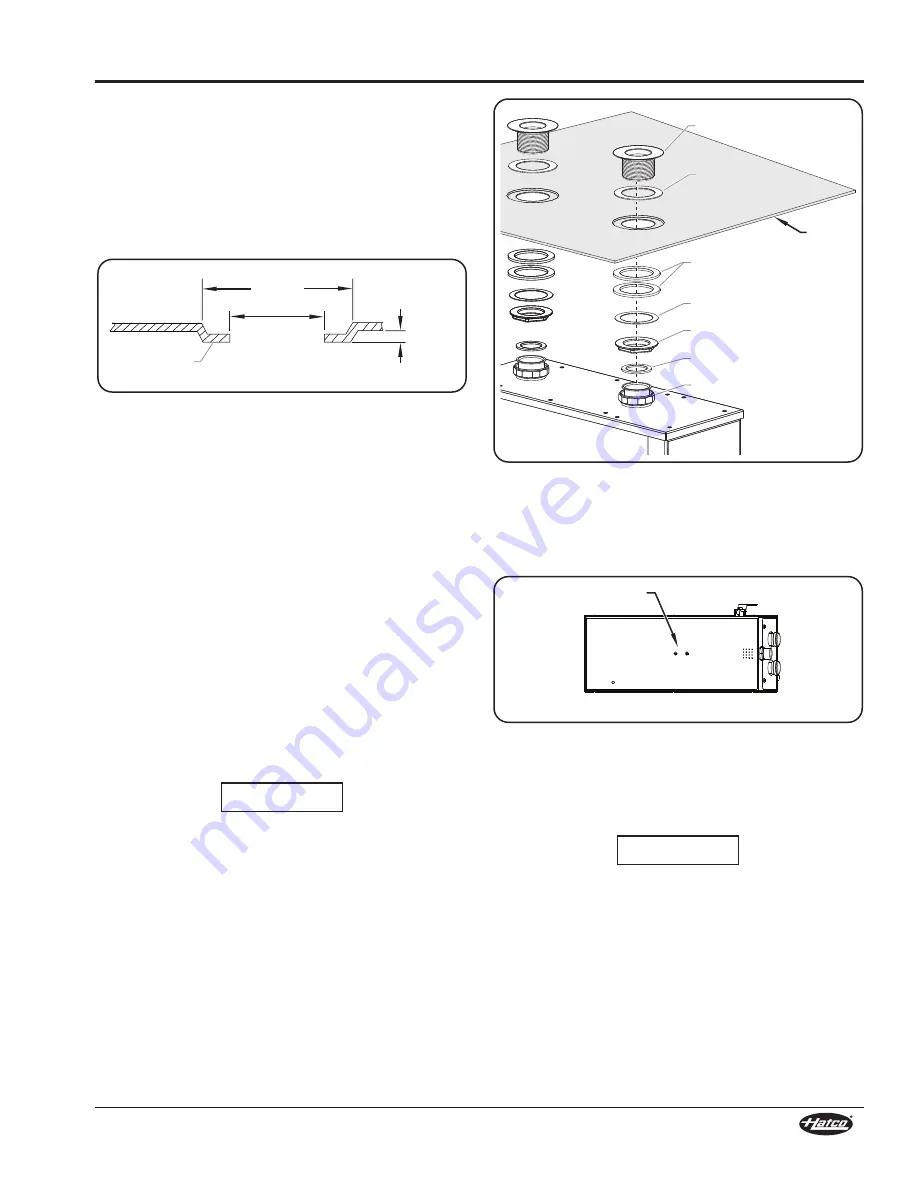

4. Make a 1/8" (3 mm) offset around each 2" (51 mm)

diameter hole. The offset should be a diameter of 3"

(76 mm) centered around the hole.

Side View of Hole and Offset

5. Unscrew the drain spud assembly from the welded pipe on

the heater.

6. Unscrew the locknut from the drain spud assembly and

slide off all of the washers except the thin rubber washer.

7. With only the thin rubber washer attached to the drain

spud, slide the drain spud through the sink hole from

above.

8. Secure the drain spud assembly to the sink or holding

vessel.

a. From under the sink, slide the two thick rubber washers

followed by the fiber washer onto the drain spud.

b. Screw the locknut (flat side up) onto the drain spud.

9. Repeat steps 5–8 for the other spud assembly.

10. Secure the unit to the sink or holding vessel.

a. Position the unit under the two spud assemblies.

NOTE: Make sure the union washers are positioned properly

inside the union nuts and are not crimped.

b. Screw the union nut to the threaded drain spud

assembly.

Do not use excessive force when tightening unions or

nuts. Over-tightening and excessive force may cause

leaks.

11. Tighten all of the nuts securely.

NOTE: Refer to the

OPTIONS AND ACCESSORIES

section for

Auto-Fill installation information.

12. Fill the sink or holding vessel with water and check for

leaks.

NOTE: A 3/4" (19 mm) hose or pipe may be connected to the

heater drain and run to an open sight drain. The heater

drain should not be permanently connected to the

sanitary drain system. The clean-out brush must have

access to the heater drain(s). Check local plumbing

code for proper drain installation. See the Maintenance

section for more information.

2”

(51 mm)

Dia. Hole

3”

(76 mm)

Dia. Offset

1/8”

(3 mm)

Offset

Height

Sink or Tank

Bottom

NOTICE

Installing a Hydro-Heater

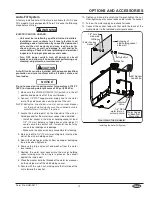

NOTE: Units exposed to movement, such as shipboard

installations, must be stabilized before operating. Two

anti-sway anchor points are located on the bottom-

center of the unit. Attach stabilization hardware to these

points using the 1/4" screws supplied.

Anti-Sway Anchor Points

Electrical Information

Hatco 3CS2 and FR2 Series Hydro-Heaters are available for

operation with standard power systems. Check the specification

label for the proper power supply.

Units are voltage-specific. Refer to specification label for

electrical requirements before beginning installation.

Connecting unit to incorrect power supply will void product

warranty and may damage unit.

Units come complete with all electrical wiring and are equipped

with three electrical knockouts, one at the rear and one on each

side toward the rear. When performing installation, run electrical

connections through one of these knockouts.

NOTE: Auto-Fill models are provided with two electrical

knockouts, one at the rear and one on the right-hand

side toward the rear.

Only specific models FR2-3 and FR2-4 Hydro-Heaters can be

ordered and supplied with an electrical cord and plug.

Thin Rubber

Washer

Thin Rubber

Washer

Drain Spud

Sink/

Vessel

Bottom

Two Thick

Rubber Washers

Fiber Washer

Locknut

Union Washer

Union Nut

NOTICE

Bottom View

Anti-Sway Anchor

Point Screws

9

Form No. HHM-0517

INSTALLATION