6

Assembly

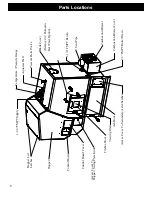

Boiler Kit Materials: (Refer to page 3)

List of items contained within the boiler kit shipped with

the unit.

1 - Control board cover

1 - Access cover (Hopper Swing Plate Knob)

5 - Spring Handles

1 - 1/2” Boiler Drain

1 - 3/4” Safety Relief Valve

1 - 1/2” Aquastat Well

1 - 1/2” Dual Temperature/Pressure Gauge

1 - 100ft. Sensor Cable (Outdoor Air Sensor)

1 - Outdoor Air Sensor

1 - Flue Tunnel Weldment

1 - Combustion Blower Assembly

1 - Heat Shield (Comb. Blower)

2 - UY Connectors

2 - Terminals 1/4 Female

1 - #8 X 1/2” TEK

3 - 1/4-20 X 5/8” Wing Screw

4 - 1/4” Lock Washer

4 - 1/4-20 Nuts

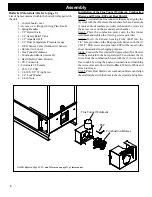

Installation of the Flue Tunnel Weldment, Combustion

Blower and Wiring, ESP and Heat Shield:

Step 1: First install the flue tunnel weldment by aligning the

(4) studs with the (4) holes in the ash chamber base. Fasten the

(4) nuts and lock washers provided, to the studs by removing

the access cover on the secondary ash chamber.

Step 2: Place the combustion motor onto the flue tunnel

weldment and tighten the (3) wing screws provided.

Step 3: Insert the Exhaust Sensing Probe (ESP) into the

1/8” hole provided on the flue pipe stub. Fasten with the (1)

#8x1/2” TEK screw also provided. ESP will be taped to the

sheet metal jacket for shipping purposes.

Step 4: Connect the flex conduit 90 degree elbow(Not Shown)

to the heat shield in the hole provided. Then connect the (3)

wires from the combustion blower with the (3) wires in the

flex conduit by using the push-on connectors and matching

the wire colors as follows: Red to Black, White to White and

Green to Green.

Step 5: Place Heat Shield over combustion blower and align

the swell latches with the holes in the sheet metal and tighten.

Heat Shield

NOTE: Refer to Fig’s 22, 23, and 24 located on page 33 of this manual.

Flue Tunnel Weldment

ESP

Combustion Blower

Summary of Contents for PB 105

Page 2: ......

Page 45: ...45 Service Record Notes...

Page 46: ...46 Service Record Notes...