7

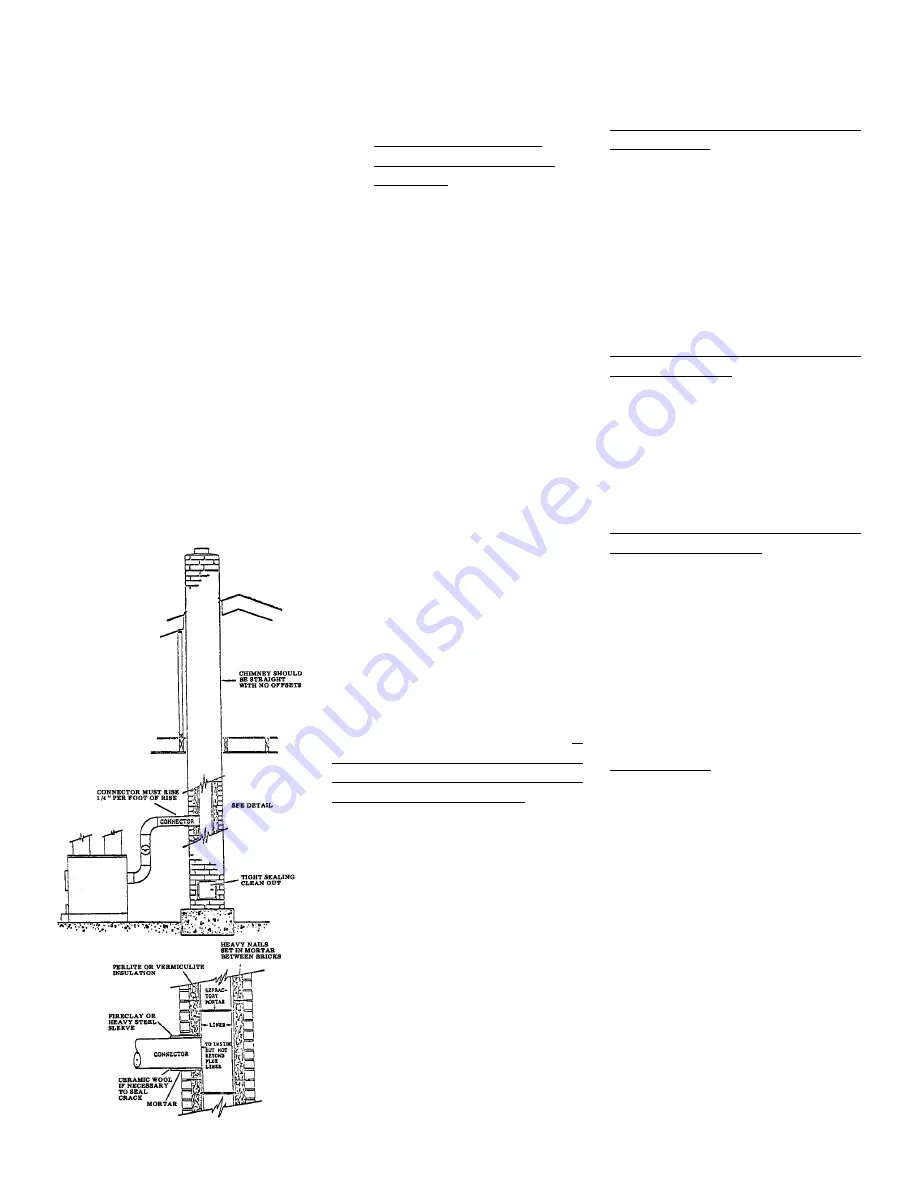

The most common cause of poor

draft is an improperly sized flue

liner. We recommend that the chim-

ney liner’s inside dimensions be at

least as large as the appliance’s col-

lar size and no larger than 125% of

the collar for a round flue. For

instance, an 8" furnace collar is 50

square inches; increased by 25"%

would be 63 square inches, or

approximately a 9" round flue. In

general for round liners we recom-

mend that they not be increased

more than 1" from that of the

Harman’s collar size. The reason for

the above is that Harman appli-

ances are designed to produce the

maximum amount of heat per

amount of fuel burned. A a result,

the flue gas temperature is lower

than for some similar equipment.

TO SUMMARIZE, A HEAT I N G

UNIT CAN PERFORM ONLY AS

WELL AS ITS VENTING SYSTEM

WILL ALLOW IT.

5. Creosote

and Soot

5.1 General and Specific

C reosote Maintenance

Wa rn i n g s

One of the most critical aspects of

operating a woodburning stove is

the control of creosote and soot.

This is especially important when

there is a low demand for heat, such

as in the fall or spring. A good

understanding of the causes and

cures for excess creosote or soot

formation is essential to the opera-

tion of the stove.

Your stove and for that matter, all

types and makes of woodburning

equipment will give trouble with cre-

osote deposits under certain condi-

tions. You should be aware of these

conditions and avoid them.

When wood is burned slowly, it pro-

duces acetic and other pyroligneous

acids that combine with expelled

moisture to form creosote. Highly

combustible in its solid and semi-liq-

uid states, creosote is present in the

gases given off by burning wood.

Creosote may build to a consider-

able thickness on the interior sur-

face of the chimney and stove pipe

subsequently reducing draft. A

SERIOUS FIRE MAY BE IGNITED

IF A SUFFICIENT CREOSOTE

BUILDUP IS PERMITTED.

Creosote condenses from the flue

gases more quickly when the tem-

perature of those gases is low. The

actual amount of creosote deposited

depends on (1) the amount of mois-

ture in the flue gases, (2) the tem-

perature of the stack, (3) the rate at

which the wood is burned, (4) the

amount of draft in the stack, and (5)

how completely the combustible ele-

ments in the flue gases have been

burned in the combustion chamber.

Most problems with creosote are

due to insufficiently dry wood, poor

chimneys with low draft and cold

walls, and/or a low rate of burning

when little heat is required during

the spring and fall months.

Moisture in the Flue Gases May Be

Controlled by:

A. Using properly seasoned fire-

wood.

B. Mixing small pieces with every

full load.

C. Never using only large (usually

less dry) wood during mild weather

when combustion is relatively slow.

The Temperature in the Stack May

be Controlled by:

A. Using as short a length of

stovepipe as possible between the

stove and the chimney.

B. Using an insulated flue pipe to

connect the stove to the chimney.

The Amount of Draft in the Stack

May be controlled by:

A . Having as few bends as possible.

B. Insuring adequate chimney

height and preventing air leaks.

C. Eliminating external obstruc-

tions in the chimney outlet.

D. Having only one appliance per

flue.

C A U T I O N ! O W N E R ’ S

R E S P O N S I B I L I T Y

YOU MUST CHECK YOUR

CHIMNEY FLUE PIPE CONNEC-

TOR FREQUENTLY WHEN FIRST

STARTING TO BURN WOOD TO

DETERMINE THE AMOUNT OF

CHIMNEY MAINTENANCE (CLEAN-

ING) THAT WILL BE REQUIRED.

THIS OF COURSE, IS ALSO

DEPENDENT ON WOOD TYPE,

MOISTURE, AND IN GENERAL,

HOW THE STOVE IS USED.

The chimney connector and chim-

ney should be inspected at least

twice monthly during the heating

season to determine if a creosote

Summary of Contents for SF-150 SF-250

Page 18: ...17...