22

Performa

™

Winch

60.2 STP E/HY

Installation and Maintenance Manual - Mod.D

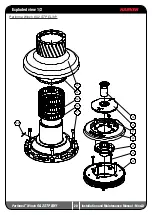

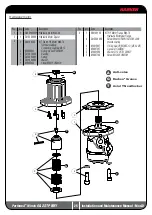

Parts list

Performa Winch 60.2 STP E/HY

Pos Q.ty Code

Description

1

1

1

1

2

A96574500

S476030004

S4130900A7

S415580085

Performa Assy Base W60 EL/HY

W60 Performance Base

Centering bushing Ø12

Bushing Ø22xØ25x8.5

Bushing Ø12xØ35x9

Winch Product Sticker**

2

1

S414400004

Gear Z14 W60

3

1

S413030004

Pawls Carrier Ø8xN2

4

6

S000090004

Racing pawl Ø8*

5

6

S000380001

Pawl Spring Ø8*

6

1

S414390041

Ratchet Gear Z21xN2

7

1

S413120002

Washer Ø22.5xØ45x1

8

1

S278170002

Washer Ø12.5xØ48x1.5

9

1

S281010004

Pin for gear

10

1

S414420041

Ratchet Gear Z26xN4

11

1

S414410004

Pawls Carrier Gear Z13 N4

12

2

A72821800

Roller Bearing Ø14xØ20x18

13

1

S416030004

Gear Pin Ø12xØ18x52,5

14

1

S414480004

Idler and Pinion Z23/Z13 W60

15

2

A74162300

Roll bearing Ø24xØ18x18

16

1

2

1

A94143100

S415580085

S4130900A7

Assy Housing Winch 60.2

Housing W60

Bushing Ø12xØ35x9

Support Bushing W60

Bushing Ø22xØ25x8.5

17

6

M0606303

Screw M8x25 UNI 5931

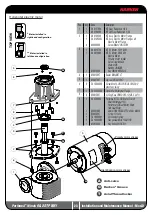

Pos Q.ty Code

Description

18

3

A74145000

Roller Bearing Ø95xØ107x26

19

1

1

A96753600

S413880002

Assy Central Shaft Winch 60 EL/HY

Central Shaft Pred. W60

Washer Ø17.2xØ32x1.5

20

Winch Serial Number Sticker

21

1

S4144300A0

Stripper Arm Housing W60/70

22

1

1

4

A96555900

S414850080

S018520001

Performa Assy Jaws W60

Lower Jaw W60

Upper Jaw W60

Peeler W60 - 70

Spring

23

1

A76537501

Performa Drum Assembly W60

24

47

M0610280

Ball 5/16"

25

4

M0601803

Screw UNI EN ISO 1207 - M6x35 - A4

26

1

S657410019

Performa Black Stripper Arm W60

27

3

M0601903

Screw M6x16 UNI1207

28

1

S4162200B1

Cover 2 Speed W60

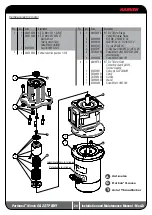

29

1

1

1

1

A94149300

S414940085

S414930003

M0679797

Assy Socket W35-80 EL/HY

Socket Handle W20/80

Washer Ø25xØ15x4

Nut Screw for Disconnect Rod

O ring RC 2025 series

30

1

S416130002

Disconnect Rod W60

*Available with service kit; see website www.harken.com

**Winch product sticker