4

.1

4

-

Spr

ay

er

setup

Gener

a

l

in

f

o

U

nlo

ad

in

g

t

h

e

spr

ay

er

f

rom

t

h

e

truck

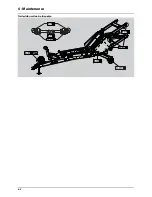

F

or

t

h

e

unlo

ad

in

g

o

f

t

h

e

spr

ay

er

, y

ou

nee

d a c

r

a

ne

. Wh

en

unlo

ad

in

g

w

it

h a c

r

a

ne

ple

a

se

o

b

ser

v

e

t

h

e

li

f

tin

g

points

a

s

s

h

o

w

n

on

t

h

e

pi

c

ture

,

a

n

d

m

ak

e

sure

t

ha

t

t

h

e

str

a

ps

or

b

elts

use

d f

or

li

f

tin

g a

re

stron

g

enou

gh.

ATTENTION! O

nl

y

li

f

t

t

h

e

spr

ay

er

wh

en

t

h

e

t

a

n

k

s

a

re

empt

y!

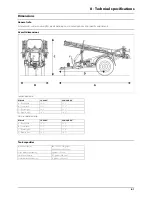

P

ullin

g

t

h

e

spr

ay

er

a

t

t

h

e

tie

d

o

w

n

h

ooks

F

or

mo

v

in

g

t

h

e

spr

ay

er

or

lo

ad

in

g

it

to

e

.g. a

tru

ck,

it

ca

n

b

e

pulle

d

in

t

h

e

h

oo

k

s

a

t

t

h

e

re

a

r

-

en

d (A)

or

a h

oo

k ca

n

b

e

fa

stene

d

into

t

h

e

h

ole

in

t

h

e

f

ront

en

d

o

f

t

h

e

spr

ay

er

(B).

B

e

f

ore

puttin

g

t

h

e

spr

ay

er

into

oper

a

tion

A

lt

h

ou

gh

t

h

e

spr

ay

er

ha

s

b

een

a

pplie

d w

it

h a

stron

g a

n

d

prote

c

ti

v

e

sur

fac

e

tre

a

tment

on

steel

p

a

rts

, b

olts

et

c.

in

t

h

e

fac

tor

y,

it

is

re

c

ommen

d

e

d

to

a

ppl

y a f

ilm

o

f a

nti

c

orrosion

oil

(

e

.g. CA

S

TROL R

US

TILO

or

S

HELL EN

S

I

S

FL

U

ID)

on

a

ll

met

a

l

p

a

rts

in

or

d

er

to

av

oi

d ch

emi

ca

ls

a

n

d f

ertili

z

ers

d

is

c

olorin

g

t

h

e

en

a

mel

. If

t

h

is

is

d

one

b

e

f

ore

t

h

e

spr

ay

er

is

put

into

oper

a

tion

f

or

t

h

e

f

irst

time

,

it

w

ill

a

l

way

s

b

e

e

a

s

y

to

c

le

a

n

t

h

e

spr

ay

er

a

n

d k

eep

t

h

e

en

a

mel

c

le

a

n

f

or

m

a

n

y y

e

a

rs

. Th

is

tre

a

tment

s

h

oul

d b

e

ca

rrie

d

out

e

v

er

y

time

t

h

e

prote

c

tion

f

ilm

is

wa

s

h

e

d

o

ff.

Support

ja

ck

Th

e

support

jack

is

store

d

in

t

h

e

b

r

ack

et

on

t

h

e

spr

ay

er

’

s

ri

gh

t

si

d

e

wh

en

t

h

e

spr

ay

er

is

a

tt

ach

e

d

to

t

h

e

tr

ac

tor

. T

o

use

t

h

e

support

jack: L

i

f

t

t

h

e

jack

o

ff

t

h

e

stor

ag

e

b

r

ack

et

. Th

e

support

jack ca

n

t

h

en

b

e

mounte

d

to

t

h

e

d

r

awba

r

e

x

tension

on

eit

h

er

si

d

e

a

s

pre

f

erre

d a

n

d

se

c

ure

d by a

lin

ch

pin

.

T

o

remo

v

e

t

h

e

support

jack: L

i

f

t

t

h

e

jack,

remo

v

e

t

h

e

lin

ch

pin

a

n

d

pull

out

t

h

e

support

jack.

Se

c

ure

t

h

e

jack a

t

t

h

e

stor

ag

e

b

r

ack

et

w

it

h

t

h

e

lin

ch

pin

.

Summary of Contents for NAVIGATOR 3000

Page 2: ......

Page 4: ...1 Welcome 1 2...

Page 14: ...6 Maintenance 6 2 Trailer lubrication oiling plan...

Page 23: ......